Our Capabilities

A wide range variety of manufacturing capabilities offer a turnkey solution that bring your projects to completion

1M +

Parts Made

300 +

Customers Served

6000

Qunique Designs

6000

Qunique Designs

Processing Capabilites Of Plastic Parts

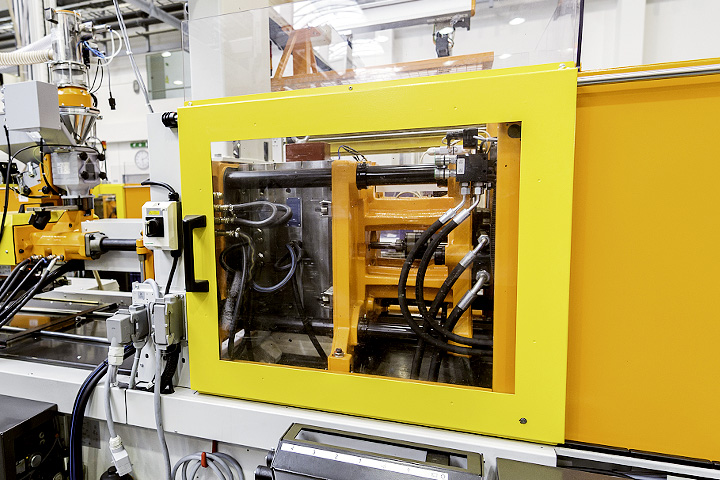

Injection Molding

Our mold making process is based on established methodologies, we can quickly transform design drawings into high-quality parts that are ready to ship within two weeks.

- Design

- Analysis

- Mold production

- Part production

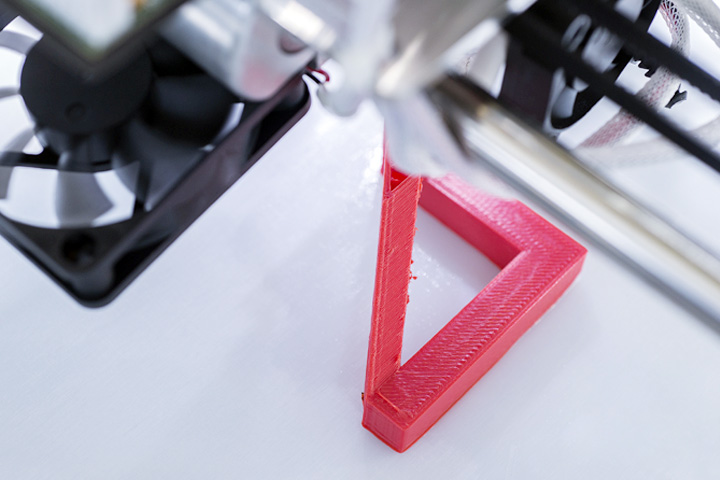

3D Printing

This is a process by which high-precision parts are made by injecting molten metal into custom-made steel. with exceptional surface finish and impressive dimensional accuracy.

- Complex geometries are possible

- Excellent surface finish and accuracy

- Mass production

Suitable for larger metal parts

Processing Capabilites Of Plastic Parts

By combining data from thousands of projects using proven material and molding techniques, our injection optimization process can quickly and easily determine correct machining parameters. These measures allow us to efficiently walk new molds through the testing phase and into production within hours.

We can complete parts quickly and correctly while achieving exceptional materials and parts geometries. We can reduce or even eliminate defection from plastic parts during the injection molding procedure.

Our Injection Molding process optimization does away with quality issues caused by molded-in stressors such as these:

3D Printing Capabilites

We rely on three additive manufacturing processes. These processes are: fused deposition modeling (FDM), stereolithography (SLA) and and selective laser sintering (SLS)

Fused deposition

modeling (FDM)

Fused deposition modeling (FDM) uses extruded melted filament through a nozzle to manufacture parts layer by layer. With a broad range of available materials, FDM works well for prototyping and in end-use production.

Stereolithography

(SLA)

SLA uses light to crosslink monomers and oligomers that form rigid polymers photochemically. This method is suitable for marketing samples, mock-ups and other non-functional conceptual samples.

Selective laser

sintering (SLS)

SLS uses a computer-controlled laser to sinter a powdered material like nylon or polyamide layer by layer. This process produces accurate, high-quality parts that require minimal follow-up or support.

Aria Vs Ohter Injection Molding Companies, What is Difference

Aria's Mold Making Process Offers Highly Competitive Advantages

Some projects require a higher production rate than others. When that happens, we build multi-cavity and automated tooling to offset extra costs with higher productivity rates and lower unit costs. In our end-to-end facility, in-house injection molding production is accom-plished using high-stability aluminum and tool steel.

Common Features of Our Injection Molding Projects

Our computerized numerical control (CNC) system and electrical discharge machining (EDM) equipment produce standard accuracies on a tool of +/- 0.005”. Tighter tolerances are available on demand with a small fee.

Processing Capabilites Of Metal Parts

Pressure Die Casting

This is a process by which high-precision parts are made by injecting molten metal into custom-made steel. with exceptional surface finish and impressive dimensional accuracy.

- Complex geometries are possible

- Massproduction

- Suitable for larger metal parts

- Excellent surface finish & accuracy

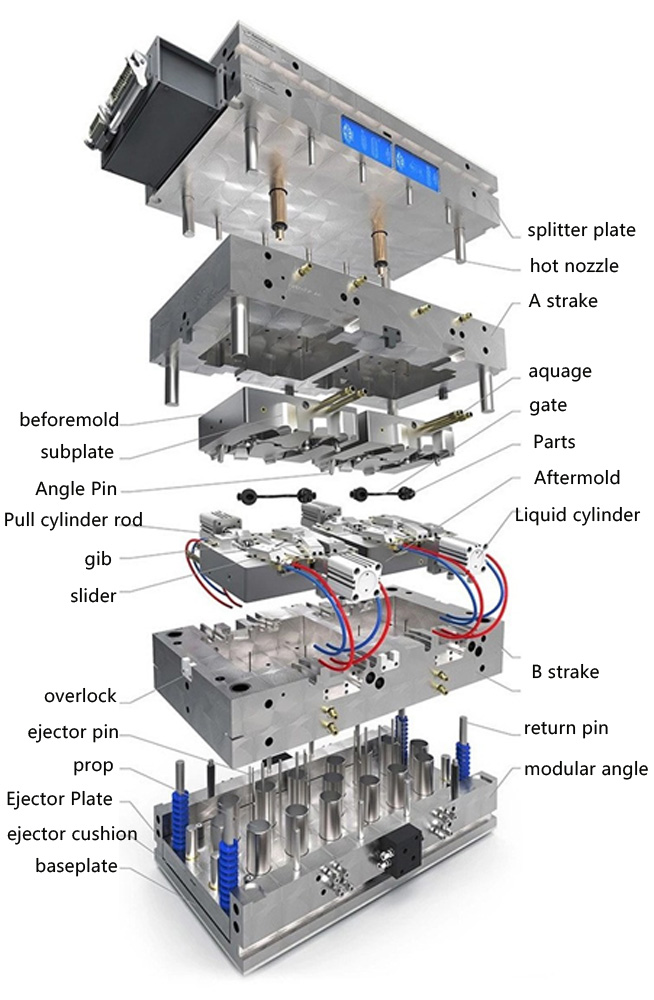

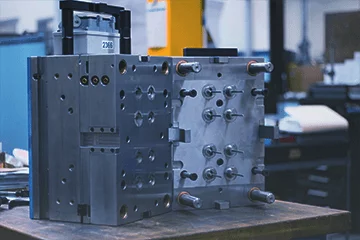

Mold Making

Our mold making process is based on established methodologies, we can quickly transform design drawings into high-quality parts that are ready to ship within two weeks.

- Design

- Analysis

- Mold production

- Part production

Sheet Metal

Sheet Metal is a cost-effective solution for metal components with a uniform wall thickness of less than 6mm. Sheet metal is appropriate for high-quality cutting, punching, bending and welding procedures.

- Parts thickness 0.5 – 10mm

- Fastest delivery 3 working days

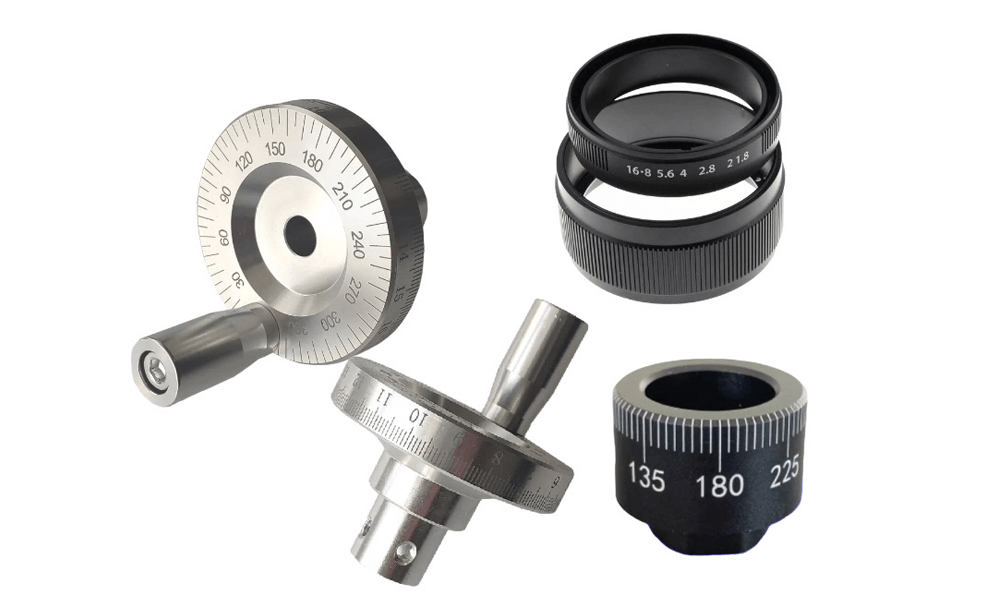

CNC Machining

This subtractive manufacturing process removes raw materials with various precision cutting tools to create parts, prototypes and finished products.

- Milling, Turning

- Wire EDM

- Surface grinding

- Electrical discharge machining (EDM)

DFM Analysis Support

A design for manufacturing analysis (DFM) is used to determine whether the design of a part is compatible with the desired production method. DFM reports focus on these variables:

Reducing tooling costs

The computerized CNC machine cuts through the metal piece and produces an exact design with minimal waste. they are environment friendly and will save a lot of money and manpower.

Limiting design change costs

We design parts to correspond as closely as possible to the original design. However, modifications may be necessary to meet the fundamental requirements of a process.

Expediting the manufacturing process

An initial analysis will be conducted based on an appropriate 3D design file. Our goal is to ensure that the parts in question are suitable for injection molding, CNC machining, 3D printing and other select procedures.

Guaranteeing quality parts

The CNC milling process uses CNC machines that are not that complicated to assemble. CNC machines are most easy to assemble and use. The manual assembly is straightforward, and even a single person can assemble the entire machine.

Processing Of Materials

CNC Machining

Aluminum

Stainless steel

Mild, Alloy & Tool steel

Other Common Metals

5052

201

Mild steel 1008

Brass 260

5083

303

Mild steel 1018

Brass 2680

6061

304

Mild steel 1020

Brass 360

6061-T6

316

Mild steel 1025

Brass 385

6061-T651

316L

Mild steel 1045(#45)

Brass H59

6063

401

Alloy steel 1215

Brass H62

6082

410

Alloy steel 4041

Bronze

ADC12 (A380)

416

40Cr steel

Copper 101

416L

Alloy steel 4130

Copper 110

420

Alloy steel 4137

Titanium TC2

430

Alloy steel 4140

Titanium TC4

440C

Alloy steel 4040

Titanium TC5

Tool Steel A2

Tool Steel A3

Tool Steel D2 (Mould steel)

Tool Steel S7

Plastic Materials

Commom Plastic

Reinforced Plastic

ABS

Garolite G-10

Polypropylene

Polypropylene (PP) 30%GF

Nylon 6

Nylon 30%GF

Delrin (POM-H)

FR-4

Acetal (POM-C)

PMMA (Acrylic)

PVC

PEEK

HDPE

UHMWPE

Polycarbonate

PET

PTFE (Teflon)

Additional Capabilities

Stamping

Stamping is a fast and efficient solution. Using the press, a tool and die surface shapes the metal into its desired form. Blanking, punching, bending, coining, embossing and flanging are all stamping methods used to shape metal.

Laser marking

Laser marking works well for making permanent markings on the surfaces of metals and certain plastics. The process doesn’t change part geometries or interfere with the mechanical properties of the substrate.

Assembly

Light commercial assembly is available both in-house and from a subcontractor. Because there are so many application possibilities, we suggest that you clarify your needs with an account manager before diving in.

Custom packaging

Custom packaging. Metal joinery is available in the form of welding, soldering and brazing. However, we only outsource these services for select projects.

Engineering Support

Our experienced engineering team is always ready to offer assistance. You will receive professional suggestions from early-stage model selection to money-saving tips and technical reminders before manufacturing. This includes custom prototype design advice.

After-Sales Service

At Aria, quality is our top concern. We deliver SGS, or RoHS metal certification, and 4D reports.

Upon request, our “Parts Verification Process” is available. For added protection, we have a generous return and refund policy.

Get A Free Quote For Your Project Today

All information and uploads are secure and confidential.

Frequently Asked Questions

CNC machining is a wide-ranging manufacturing category involving multiple computer-managed processes. The objective is to remove enough raw material from a piece to achieve a state of near completion.

Aria is a professional CNC machining manufacturer in China, The reliability and precision of high-tech tools powered by sophisticated software programs give CNC machining the ability to quickly generate prototypes and complicated end-use parts having exceptionally tight tolerances. with low cnc machining costs from Chinese.

CNC machining is a subtractive manufacturing process. When the material is added instead of removed, it’s called an additive manufacturing process. Examples of subtractive CNC machining include specialized applications such as CNC milling services, turning, surface grinding, and EDM. An example of additive CNC machining is 3D printing.

Computer-aided design (CAD) files are digital records containing 3D designs and information about materials, processes, tolerances, and other variables. A digitally controlled CNC machine must always contain a file of the part design that controls it.

The spinning motion from the CNC machine’s cutter will leave visible tool marks. Although they stand ready for immediate service, they can be further refined with anodizing, painting, polishing, and plating.