CNC Milling Services

CNC milling services can produce complex and precise parts with high accuracy and repeatability, making them a popular choice for prototyping, custom parts, and mass production.

Start A CNC Milling Quote

MOQ

1 Pcs

Fastest Delivery

3 Days

Unique Designs

6000 +

Shipping

WorldWide

Type of CNC Milling Services

Aria offers 3-axis, 4-axis, and 5-axis CNC milling services to create complex geometric shapes with high accuracy. Our machining team can help customers control their CNC milling projects and ensure that the custom parts meet their strict requirements.

3 axis CNC milling

This CNC milling process can be moved on the X, Y, and Z axes and can only do surface milling. It is suitable for manufacturing two-dimensional or simple three-dimensional parts, such as flat and simple curve parts, models, etc.

4 axis CNC milling

4 axis milling machines can rotate around A fixed axis, often referred to as the A-axis or axis of rotation, in addition to moving on the X, Y, and Z axes. This process can be used to process complex three-dimensional parts.

5 axis CNC milling

This milling machine has the ability to move on the X, Y, and Z axes and rotate around two axes of rotation (A and B). The 5-axis CNC milling machine can handle more complex shapes, it is suitable for high precision parts manufacturing.

Advantages of Aria’s CNC Milling

1. Speed

Aria offers a quick turnaround time for CNC machined parts, with some parts able to be produced in as little as one day.

2. Quality

With multiple quality checks throughout the production process to ensure the final product meets your specifications.

3. Materials

Aria offers a wide variety of materials to choose from, including metals, plastics, and composites, to suit different applications and industries.

4. Prototyping

Aria offers prototyping services, allowing you to test and refine your design before moving to full-scale production.

How does it work?

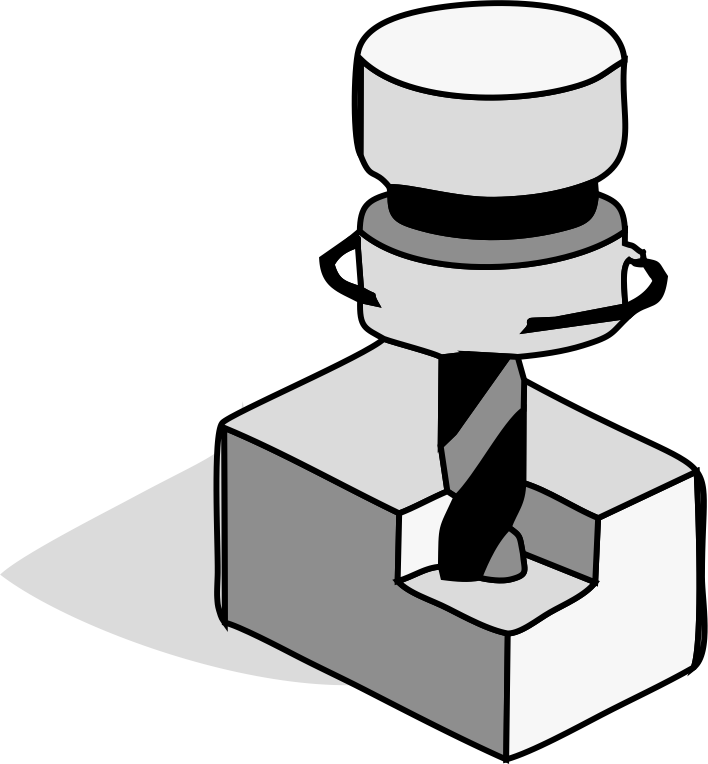

CNC (Computer Numerical Control) milling is a process used to create complex and precise shapes by removing material from a workpiece using a cutting tool controlled by a computer program. Here’s how it works:

Design:

The first step in CNC milling is creating a 3D digital design of the part or component to be milled using computer-aided design (CAD) software. The design is then converted into a format that can be read by the CNC milling machine.

Programming:

The converted design is loaded into the CNC milling machine's computer control system, which converts it into machine-readable code (G-code). This code contains instructions on how the cutting tool should move and remove material from the workpiece.

Setup:

The workpiece is then secured onto the milling machine's worktable using clamps or other methods. The cutting tool is also installed and adjusted according to the required specifications.

Milling:

Once everything is set up, the CNC milling machine is started, and the cutting tool moves according to the G-code instructions. The cutting tool removes material from the workpiece in a series of passes until the desired shape is achieved. During the milling process, the cutting tool may need to be changed or adjusted to achieve the desired result.

Finishing:

After the milling process is complete, the workpiece may require additional finishing steps, such as sanding or polishing, to achieve the desired surface finish.

Available materials for CNC Milling Services

Metal Materials

Aluminum

Stainless steel

Mild, Alloy & Tool steel

Other Common Metals

5052

201

Mild steel 1008

Brass 260

5083

303

Mild steel 1018

Brass 2680

6061

304

Mild steel 1020

Brass 360

6061-T6

316

Mild steel 1025

Brass 385

6061-T651

316L

Mild steel 1045(#45)

Brass H59

6063

401

Alloy steel 1215

Brass H62

6082

410

Alloy steel 4041

Bronze

ADC12 (A380)

416

40Cr steel

Copper 101

416L

Alloy steel 4130

Copper 110

420

Alloy steel 4137

Titanium TC2

430

Alloy steel 4140

Titanium TC4

440C

Alloy steel 4040

Titanium TC5

Tool Steel A2

Tool Steel A3

Tool Steel D2 (Mould steel)

Tool Steel S7

Plastic Materials

Commom Plastic

Reinforced Plastic

ABS

Garolite G-10

Polypropylene

Polypropylene (PP) 30%GF

Nylon 6

Nylon 30%GF

Delrin (POM-H)

FR-4

Acetal (POM-C)

PMMA (Acrylic)

PVC

PEEK

HDPE

UHMWPE

Polycarbonate

PET

PTFE (Teflon)

Tolerance for CNC Milling Services

Limits for nominal size

Metals (ISO 2768- f)

Plastics (ISO 2768- m)

0.5mm* to 3mm

±0.05mm

±0.1mm

Over 3mm to 6mm

±0.05mm

±0.1mm

Over 6mm to 30mm

±0.1mm

±0.2mm

Over 30mm to 120mm

±0.15mm

±0.3mm

Over 120mm to 400mm

±0.2mm

±0.5mm

Over 400mm to 1000mm

±0.4mm

±0.8mm

Over 1000mm to 2000mm

±0.5mm

±1.2mm

Applications of CNC Milling Services

The CNC milling services can be used for various purposes, but it has been a massive part of the metal industry. They have been used in places where metal cutting is required according to the designs, and such cuttings must be done very precisely.

Automotive

Aerospace

Consumer Goods

Medical Devices

Electronic Component

CNC Machining FAQs

A: CNC machining is a wide-ranging manufacturing category involving multiple computer-managed processes. The objective is to remove enough raw material from a piece to achieve a state of near completion.

A: Aria is a professional CNC machining manufacturer in China, The reliability and precision of high-tech tools powered by sophisticated software programs give CNC machining the ability to quickly generate prototypes and complicated end-use parts having exceptionally tight tolerances. with low cnc machining costs from Chinese.

A: CNC machining is a subtractive manufacturing process. When the material is added instead of removed, it’s called an additive manufacturing process. Examples of subtractive CNC machining include specialized applications such as CNC milling services, turning, surface grinding, and EDM. An example of additive CNC machining is 3D printing.

A: The spinning motion from the CNC machine’s cutter will leave visible tool marks. Although they stand ready for immediate service, they can be further refined with anodizing, painting, polishing, and plating.

Aria supply online cnc machining service, Get Your Free Quote About cnc machined parts Today.

All information and uploads are secure and confidential.

CNC Milling Resources

What is CNC milling? Ultimate Guide 2022 | MadeAria

The first CNC milling machines were created in the 1950s as a response to the need for more precise and repeatable machining

Custom CNC Machining Services- What is a 5 Axis CNC Machine?

CNC machining services, also known as custom CNC machining, allow businesses to offer unique, high-quality parts that are customized to fit their

Which parts need to be finished by CNC machining?

CNC machining in the status of CNC equipment is very high, many parts processing enterprises will be applied to CNC machining center,