一.Mould Quality

1. The smoothness of the injection surface of a mold

The polishing of the die surface is very important, which is one of the most important links to determine the success or failure of die manufacturing. The surface of the mold is not smooth enough, its surface is uneven, and the texture of the plastic products will be leathery and sand grains. Generally, it is better to polish the surface into a mirror. In addition to the choice of steel in the mold, the polishing personnel, time, and technology will affect the polishing mirror effect. It is required to have a mold polishing master and rich experience to accurately master the polishing time and ensure the effect after the mirror polishing of the mold.

2. Precision of mold

The precision of the mold determines the dimensional precision of plastic parts. The mold manufacturing should first have the measurement conditions, such as the two-dimensional, three-dimensional, and other detection instruments. The object imaging principle is used to accurately calculate the size and spatial position of the object, which can detect the difference of 0.02mm and accurately measure the product size and injection volume.

3. The fit degree of mold production

Mould industry despite the operation standard, but different mold manufacturers of mold and injection molding, there will be any of the minute differences such as open mold and injection molding is not the same companies, for various manufacturers of mechanical equipment and production methods, production will exist in the risk, affect the product quality and production efficiency, to reduce this risk, usually selected companies in the same mould and injection molding is better, From mold opening to injection molding processing manufacturers can control, problems can be solved in time.

二.How do plastic injection molding mold surface gloss defects?

Plastic injection moulds will appear a lot of difficulties. Injection mold consists of two parts, dynamic model and the fixed mold, the production of plastic products need mold injection molding, is through the injection molding machine of plastic raw material into the mold cavity, after cooling solidification for forming of plastic injection parts, in the process of mould manufacturing. Plastic injection molding processing of mould surface gloss defects to do?

The following summarizes Aria plastic injection mold surface gloss defects and solutions, and I hope to help you.

- Poor die finish, rust on the surface of the cavity, and poor die exhaust.

- The casting system of the mold is defective, so the cold well should be increased,

- and the flow channel, polishing the main channel, shunting channel, and gate should be increased.

- The material temperature and mold temperature are low. When necessary, a local heating method can be used at the gate.

- Plastic is the thick wall to be fully plasticized, but it needs to prevent material degradation, heat to be stable, cooling to be full.

- Prevent cold material from entering parts, use a self-locking spring or reduce nozzle temperature when necessary.

- The use of recycled material is too much, plastic or coloring agent quality is poor, mixed with water vapor or other impurities, and lubricant quality is poor.

- Clamping force should be enough.

Categories

Share On

Recent Post

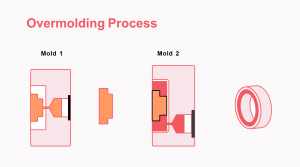

What is Overmolding? A Complete Guide

In today’s manufacturing world, creating durable, functional, and aesthetically pleasing

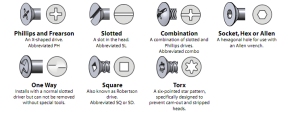

A Complete Guide on the Types Of Screw Head

You’ve probably stood in front of a confusing display of