Injection molding is a manufacturing process in which molten materials can be injected into a mold for mass production. Among molding materials used are thermoplastics that melt when heated. There are different plastic injection molding materials that differ in physical, chemical, and mechanical properties. Therefore, it is important to understand different plastics to avoid any conflict during prototyping and production processes. The ten most commonly used plastic injection molding materials are:

#1. Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic of engineering-grade with a low melting point that makes it easy to mold. Available with various surface finishes and textures, its opaqueness supports the use of colorants. It is considered one of the best plastic injection molding materials because of its impact resistance and strength. It found its applications in various electronic components, keyboard keys, plastic wallplates, protective headgear, consumer goods, industrial fittings, sports equipment, and automotive parts, including auto body parts, wheels covers, and dashboards.

- Advantages

Resistant to acids,

alkalis, oils, and heat

Relatively inexpensive

High strength

Provides shiny and attractive finish

Possess toughness at low temperature - Disadvantages

Lacks resistance to weather,

high friction,

and solvents like water

Emits smoke when burned

- Grades and Brands

Common brands associated with acrylonitrile butadiene styrene are BASF Terluran, Ineos Lustran, Samsung Starex, and Toray Toylac. When combined with fillers, its strength increases. Further, when compounded with polycarbonate, it increases its impact resistance at low temperatures.

#2. Nylon Polyamide (PA)

Nylon polyamide is a kind of polyamide that is synthetic in nature. An injection molded nylon polyamide is vulnerable to inadequate filling and shrinkage. It is usually used in different mechanical parts like bearings, gears, slides, and bushings. It can also be used for castings, threaded inserts, jigs and fixtures, and kinetic parts. Additionally, it found its applications in the toothbrush, wheels, electrical connectors, and medical implants.

- Advantages

Resistance to high temperatures, abrasion, noise dampening, and fatigue

Exceptional toughness

Low coefficient of friction

Suitable for wear applications - Disadvantages

Non-resistant to flame, though there is the availability of flame retardant versions

Degradation by ultraviolet stabilizer, sunlight Lack resistance to strong bases and acids - Grades and Brands

DuPont developed the nylon polyamide, though it comes under different brand names. Four important grades of nylon polyamide, Nylon 11, 12, 46, and 66, differ in mechanical properties. Nylon 11 has excellent moisture resistance that enhances its resistance to changes in dimensions, making it useful for outdoor applications. With the lowest melting point among different nylon grades, Nylon 12 is resistant to water absorption. Nylon 46, compared to other nylon grades, has a relatively high operating temperature and thus, can be used for engines and transmissions. Finally, Nylon 66 is usually used in chemical processing applications due to its higher melting point and good resistance to acids. Further, when compounded with glass fillers, all these nylon grades can help increase nylon polyamide’s mechanical strength.

#3. Polyethylene (PE)

The most used plastic material globally, polyethylene, is the only commercial polymer. Its three important types are high density (HDPE), low density (LDPE), and polyethylene terephthalate (PET). LDPE, PET, and HDPE are cost-effective plastics. LDPE and HDPE are chemical resistant but differ in hardness, optical transparency, flexibility, and melting point. Unlike HDPE, an opaque material, PET and LDPE are highly transparent. HDPE is relatively hard and less flexible than LDPE. Density cannot define PET plastic. These are used as blow molding materials in plastic films, water bottles, and milk bottles. An injection-molded polyethylene is used in toolboxes, children’s toys, cable insulators, electronic wire, and components in different medical devices.

- Advantages

Resistance to chemicals and moisture

Wide range of optical clarity - Disadvantages

Poor ultraviolet resistance

Resistance to higher temperatures

HDPE is thick, which makes it hard to mold

Resin drying is required by PET

LDPE makes it hard to achieve tolerances

High production costs - Grades and Brands

Polyethylene plastics have different numbered grades. Grades of higher numbers depict higher density. For instance, LDPE has a lower density than HDPE 500 and HDPE. The branded suppliers of polyethylene are DuPont and BASF. They supply LDPE, HDPE, and PET for engineering applications instead of general-purpose.

#4. Polycarbonate (PC)

Polycarbonate plastics are used as common plastic injection molding materials due to their strength, toughness, and transparency. Its physical properties are retained at extreme temperatures. After pigmentation, polycarbonate retains its strength while maintaining its color. Its properties help it find its applications in clear windows, light-emitting diodes, machinery guards, and clear tubing. Also, an injection molded polycarbonate can produce clear molds for silicone and urethane casting.

- Advantages

Extremely durable

Lightweight

Support light transmission

Excellent optical properties

Mold shrinkage is uniform

Provides precise dimensional control - Disadvantages

It contains Bisphenol A (BPA) and cannot be used in food preparation or food storage

High processing temperature

Expensive

Non-resistant to scratch - Grades and Brands

PC can be used with a glass filler or compounded with Acrylonitrile Butadiene Styrene for increasing its impact resistance. There are some polycarbonate grades that have a small amount of stainless steel (SS) fiber. Polycarbonate is available with Covestro Makrolon and SABIC Lexan.

#5. Polypropylene (PP)

The second most used plastic globally, polypropylene, is heat resistant and harder than polyethylene. Pure PP has the lowest density and thus is used as commodity plastic. The density of PP can be enhanced with different fillers. Polypropylene finds its applications in various commercial, industrial, and consumer products. For example, an injected molded polypropylene is used in storage containers, packaging, children’s toys, sporting goods, power tool bodies, and appliances.

- Advantages

Resistant to chemicals

Retain shape for a long time

The melting point is high

Don’t degrade when contact with moisture

Recyclable - Disadvantages

Degrades with ultraviolet light

Extremely flammable

Dissolves into aromatic hydrocarbons that adversely affects human

Health

Difficult to paint and bond - Grades and Brands

Polypropylene can be mixed with fiberglass to increase strength, rigidity, warping resistance, and dimensional stability. Different grades of PP are regular polypropylene and high crystalline polypropylene. The leading supplier of polypropylene is Semitron.

#6. Polymethyl Methacrylate (PMMA)

Polymethyl Methacrylate, commonly known as acrylic, is a strong and clear thermoplastic. Its lightweight and shatter-resistant properties make it an excellent alternative to glass. Because of optical clarity and transparency, a higher percentage of light can pass through it. PMMA is commonly used in solar panels, greenhouses, bathroom enclosures, windows, and other lighting and architectural components.

- Advantages

High tensile strength

Resistance to sunlight and weather

It doesn’t degrade with moisture

Don’t release Bisphenol A (BPA) - Disadvantages

Expensive than glass

Prone to scratches and stress cracking

It can be stained by oils and greases

Low temperature for industrial applications

Lacks resistance to strong solvents - Grades and Brands

There are three types of acrylics: general-purpose, marine-grade, and sign-grade. General-purpose acrylic is mainly used in commodity products. Compared to general-purpose acrylic, sign-grade acrylic has 10x strength and is used for outdoor signage. Marine-grade acrylic is water-resistant and finds its application by boat builders. Leading suppliers of PMMA include DuPont LUCITE (optical clarity and transparency) Trinseo PLEXIGAS (resistance to high temperature).

#7. Thermoplastic Elastomer (TPE)

A thermoplastic elastomer is also known as TPR (thermoplastic rubber) since it is a mixture of plastic and rubber materials. Though it has mechanical properties the same as that of rubber, its processing is done like plastic. As the name suggests, it has high elasticity and is recyclable almost six times. Further, it can make compounds with different recycled materials. An injection molded thermoplastic elastomer can be used in manufacturing footwear, automotive parts, pet products, and medical devices. Its applications include ventilation masks, valves, breathing tubes, catheters, shock dust boots, and weather seats.

- Advantages

High elasticity

Molding cycles are shorter

Cost-effective to mold -

Disadvantages

Permanent deformation under sustained pressure

Relatively expensive

Low resistance to high temperatures -

Grades and Brands

Commercial thermoplastic elastomers (TPE) are defined by ISO 18064. Different brands associated are Kraiburg HIPEX, Teknor Apex Telcar, and Dynaflex from Avient. Further, thermoplastic elastomers are available in healthcare grades.

#8. Polyoxymethylene (POM)

Polyoxymethylene, also known as acetal, is a plastic material mainly used by engineers. An injection-molded polyoxymethylene has high stiffness, low friction, excellent dimensional stability, and a highly crystalline structure. It is naturally white in color. It is of two types: copolymers and homopolymers. It is used in bearings, conveyor belts, pulley wheels, and gears. Additionally, it is suitable for eyeglass frames, lock systems, fasteners, firearms and knives, and high-performance engineering components.

- Advantages

Excellent rigidity

Good thermal stability

Low coefficient of friction

Resistance to chemicals

Low water absorption - Disadvantages

Low impact strength

High shrinkage

Not resistant to ultraviolet light

Higher hardness

It can’t be fire-rated - Grades and Brands

Polyoxymethylene can be compounded with minerals or fiberglass to enhance stiffness, strength, and mechanical properties. Various brands associated with POM are Ensinger TECAFORM and DuPont Delrin.

#9. Polystyrene (PS)

One of the commodity plastic materials, polystyrene (PS), is of two types: General purpose polystyrene (GPPS) and High impact polystyrene (HIPS). Compared to HIPS, the dimensional stability of GPPS is low and is highly brittle. While HIPS is opaque, GPPS is transparent, having glass-like clarity. The material properties of HIPS can be enhanced by compounding it with butadiene rubber. Owing to their uniform shrinkage, both GPPS and HIPS are readily used as plastic injection molding materials. In addition, they are used in optical, medical, electronic, and electrical applications.

- Advantages

Lightweight

Inexpensive

Resistance to bacterial growth, moisture, chemicals, and gamma radiation - Disadvantages

Flammable

Prone to cracking

Susceptible to ultraviolet degradation

Not biodegradable

Vulnerable to hydrocarbon solvents, including kerosene and benzene - Grades and Brands

For enhancing the properties of polystyrene, it may be filled with fiberglass and copolymerized with acrylic. This would improve clarity, chemical, and ultraviolet stability. Associated brands include BASF Polystyrol and American Styrenics PolyRenew.

#10. Thermoplastic Polyurethane (TPU)

Though a kind of TPE, Thermoplastic Polyurethane (TPU) is considered a different material owing to its unique features. An injection-molded TPU has great resistance to chemicals and extreme temperatures. Its higher durometer makes it a good alternative for hard rubber. This is the reason why it finds its application in sporting goods, caster wheels, footwear, and gaskets. Its applications include electronics enclosures and medical devices. TPUs are used to prevent skin irritation.

- Advantages

Good load-bearing capabilities

Higher resistance to chemicals, oils, greases, abrasion, and high temperature - Disadvantages

Lack flexibility

Relatively higher pre-processing cost - Grades and Brands

The different grades of thermoplastic polyurethanes are in industrial, commercial, and medical grades. Three important grades of Thermoplastic Polyurethane are polycaprolactone, polyether, and polyester. The brands associated with TPU are Ultralast, Texin, Lubrizol, and Lanxess.

Specialty Plastic Injection Molding Materials

The plastic injection molding includes specialty materials such as PEI (Polyetherimide), PBT (Polybutylene Terephthalate), PEEK (Polyether ether ketone), LCP (Liquid crystal polymers), and PVC (Polyvinyl chloride).

PEI has stiffness and low smoke production, thus considered safe for the environment. The application of PEI is in medical components, lighting systems, and automotive transmissions due to its high impact strength.

PBT has low melt viscosity and is creep-resistant. Since its deformation takes place at a very slow pace, it is used in switches, distribution boxes, and keyboards

LCP plastic has high resistance to gamma radiation. It is used in medical devices and injection molded sockets.

PVC is an inexpensive, lightweight, and recyclable plastic. It has tensile strength along with environmental resistance. Being hard plastic, it can be used in plumbing, automotive parts, wire spools, and windows.

Blended Plastic Injection Molding Materials

Apart from the most commonly used plastic injection molding materials, blended plastics tend to be excellent molding materials due to the combination of the best properties of different polymers. Different blended plastic injection molding materials include PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene), PC (Polycarbonate)/PBT (Polybutylene Terephthalate), and PPE (Polyphenylene Ether)/PS (Polystyrene).

PC/ABS molding material is heat resistant. It has high strength and stiffness. Due to its low shrinkage property, it is used in the electronics and automotive industries to make laptop monitor enclosures and glove boxes.

PC/PBT has good resistance to chemicals, temperature, and ultraviolet. Therefore, this engineering polymer is commonly used for the insulating process in the electronic and electrical industries.

PPE/PS has low water absorption and mold shrinkage, due to which it finds its application in environmental engineering, fluid engineering, and potable water applications.

Categories

Share On

Recent Post

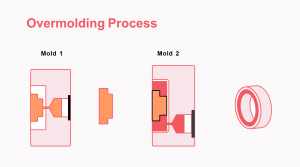

What is Overmolding? A Complete Guide

In today’s manufacturing world, creating durable, functional, and aesthetically pleasing

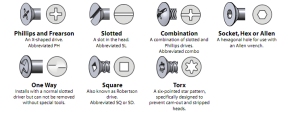

A Complete Guide on the Types Of Screw Head

You’ve probably stood in front of a confusing display of