A Guide on Injection Molding and Its Application in Automotive Parts Production

A Guide on Injection Molding and Its Application in Automotive Parts Production

When it comes to the fabrication of automotive parts like the engine body, hoods, mirror casing, knobs, switches, and more, plastic is often considered to be superior as compared to metals or any other type of material. Plastic is highly flexible, cheap, and also comes with high flexibility and malleability which is why it’s so preferred. With proper fabrication technique, one can give the plastic material any shape as desired by the automotive industry. Even though there are many processes of giving the plastic different shapes, it is injection molding that can introduce more precision and accuracy in the fabrication technique.

Injection molding is a process by which molten material is injected into a closed mold till it is filled to the brim. The entire arrangement is then allowed to rest and cool down. Once the temperature starts to reduce, the molten plastic begins to solidify. As a result, the outcome takes the mold shape and is completely solid. Even though there are several challenges a fabricating automotive parts company has to go through, the benefits of the process can’t be left unacknowledged.

Owing to this, we have prepared a complete guide on injection molding while keeping our focus mainly on its various applications in the automotive industry.

How is injection molding carried out for manufacturing automotive parts?

The process of injection molding comprises a series of steps where proper precision and accuracy need to be implemented. But first, let’s discuss what a mold is because that is the most important component of the process.

A brief introduction to molds

The molds used in the process of injection molding are usually made from metals or alloys like steel, aluminum, stainless steel, and more. These materials are not only strong but are able to withstand a high amount of heat also since molten plastic has to be poured into them. The inner walls of the molds are shaped in the form of the automotive part to be manufactured.

Process of injection molding

In injection molding, the plastic material is first converted into granular form. Usually, the pellets are used as they are very small and can easily melt at the desired temperature. The heat applied is controlled properly so that the physical and chemical properties don’t get changed.

Once the plastic is melted completely and a semi-liquid state is achieved, it is then transferred to a separate place. Now, the liquid is poured into the cavity of the closed part till it is filled to the top. Usually, the molds are cooled down properly so that, once the plastic is poured, it can instantly solidify due to the low temperature. This is why injection molding is considered to be the fastest fabrication process.

Benefits of processing injection molding

There are several reasons which can explain why injection molding is the most considered fabrication method when it comes to plastic automotive parts. In the below section, we have explained some of the main advantages of this process.

Availability of materials

One of the main reasons for preferring injection molding is the huge availability of raw materials. There are several types of different plastics or polymers that are used for molding and shaping automotive parts. From the regular polypropylene pellets to PVC and others, manufacturers make use of a wide range of polymers having the desired physical and chemical properties.

Fast and efficient

The process of injection molding is quite fast since the molten plastic can easily solidify once its liquid form is poured inside the mold. Therefore, hundreds of units can be prepared easily without any waste of time. The entire technique not only reduces the time consumption but also ensures that the parts produced have similar features, be it in the terms of looks or surface finish. Besides, the molds are in different shapes and therefore, different automotive parts can be manufactured with ease.

Cost-efficient

As the automotive parts can be fabricated in such a short time, the overall operational costs reduce by ten folds. Also, the plastic itself is a cheap raw material as compared to metals which also further reduces the costs and expenses. This is why injection molding is always preferred when it comes to the manufacturing of automotive parts in huge quantities in less time.

Precision and accuracy

The entire process of injection molding is highly accurate and precise since the inner surfaces of the molds are designed exactly in the shape of the automotive parts. Besides, plastic does not shrink and create gaps between their external surface and the inner cavity wall of the molds which is why their structures are considered to be accurate with the original model.

Excellent surface finish

Since the inner walls of the molds are smooth with no holes, dents, or rough texture, the surface finish of the automotive parts is extremely smooth with no imperfections. In fact, the fabricated parts don’t even need extensive machining and filing to achieve the perfect surface finish. This is why injection molding is said to be a compact fabrication process in itself. Whenever an imperfection is found on the inner wall of the molds, they are machined and removed to ensure that at the time of fabrication, the process can be completed with ease.

How is injection molding carried out for manufacturing automotive parts?

Injection molding has impacted the automotive parts manufacturing industry in a huge manner, albeit with more positivity. The major areas where the fabrication technique is used are described in the below section.

-Fabrication of automotive parts under the hood

In earlier days, all the components present under the hoods were manufactured from metals only. However, it was quite hard to achieve precision because these components control the entire operation of an automobile. For example, the pipes, engine body, plugs, and others, when manufactured using metal were found to be imperfect with uneven surfaces, dents or raised areas, and so on.

This is why, nowadays, plastic is used for fabricating these components through the process of injection molding. Usually, PET, ABS, and nylon are used since they are highly durable, can withstand a high temperature, and offer resistance against corrosion and damages.

-Manufacturing of external car parts

Almost 80% of the external car parts are manufactured from plastic through the injection molding process. These parts not only vary in shape and size but also some of them have complex structures. Therefore, to attain maximum precision and accuracy while maintaining the productivity of the manufacturing unit, the injection molding process is preferred.

For example, manufacturing large components like light covers, doors, hoods, and even mirror cases, is much easier due to the use of molds. Similarly, if we consider more complex car parts like grills, AC condensers, fenders, and more, they can also be manufactured easily using Injection molding. The only challenge is to design the inner cavities of the mold according to the shape of the original component design.

-Manufacturing of the internal cabin parts

There are several components present inside the car cabin which are manufactured with the process of injection molding. This not only ensures absolute perfection in the looks of the parts and their durability but also helps in the fabrication of several decorative components as well. Besides, there are several components having intricately detailed structures which are possible to achieve only with injection molding.

Materials used for injection molding automotive fabrication

Even though injection molding can be completed with different types of materials, not all of them are suitable for automotive parts manufacturing. This is because one needs to meet a lot of regulations and safety standards to make sure that the overall product manufactured can be safe on the roads. Hence, the materials chosen need to match the requirements with sheer perfection and accuracy. Moving forward, we have not only discussed different types of materials used for injection molding but also the features these materials have.

Features that the injection molding material needs to have for automotive fabrication

- The injection molding material needs to have high durability so that it can withstand wear and tear for the longest time.

- It should have a high tolerance towards temperature so that the automobile can be used in both hot and cold weather conditions.

- The material needs to have flexibility, high malleability, and ductility so that it can be given the desired shape.

- It should meet all the road safety standards and regulations as described by every country.

- Hardness, when cooled down, is always considered as one of the major factors since the car parts have to endure huge collision forces.

Before finalizing the material for injection molding, it is subjected to a wide range of tests in terms of chemical, physical, and mechanical processes. This is to ensure that it meets the safety standards and can deal with numerous stressors without suffering structural damage.

Top materials used to fabricate automotive parts with injection molding

Even though plastic is the main component used for fabricating automotive parts through injection molding, there are several types of this polymer that are used on the basis of the desired features. Below, we have described some of the major materials used in manufacturing automotive parts.

ABS

ABS or Acrylonitrile butadiene styrene is weather-resistant and comes with excellent durability. This is why the material is used for fabricating external car parts like hoods, doors, covers, and more.

Nylon

Nylon is used mainly to manufacture car parts that won’t come in contact with any liquid. For example, brushes, bearings, and other such components are often manufactured with nylon. It has high resistance against physical abrasions and chemical damages.

PMMA

Poly Methyl Methacrylate is a transparent acrylic material that not only acts as an amazing substitute for glass but also offers high resistance against shattering. From internal screens to the tail and headlight covers, several such car parts are manufactured with PMMA.

Polyurethane

Polyurethane is used for manufacturing foams, car seats, and other soft components since the material is super flexible and its hardness can be altered at the time of manufacturing. Solid components like suspension bushes, gaskets, seals, and insulation panels are also fabricated with this material.

Polypropylene

Polypropylene is one such plastic polymer that shows excellent resistance against water, UV radiations, temperature, and chemicals. Therefore, it is often used to manufacture external components of the cars through injection molding. Besides, the material is easy to melt and hardens almost instantly as soon as it is poured into the cavity of the molds.

PVC

Another common material used in the manufacturing of automotive parts is PVC, thanks to its resistivity to heat and chemical abrasions. Besides, the material can withstand several types of mechanical damage which is one of the main concerns of automotive part manufacturers.

Challenges to be faced during injection molding for fabricating automotive parts

Even though injection molding has many benefits and is often considered to be the best method for fabricating different automotive parts, there are some challenges that one needs to face. In the below section, we have listed some of these hardships that need immediate addressing so that the entire process can be optimized.

-Mold fabrication costs

Even though plastic is cheap and can reduce operational costs, the same can’t be said about the materials with which the molds are manufactured. Until and unless you have the molds, you won’t be able to proceed with injection molding. Also, when new and developed parts are introduced, the previous molds either need to be reconstructed or disposed of.

-Difficult to achieve complex designing

There are several parts in the car or any other automotive structure that comes with complex designs. For example, the accelerators, gear wheels, piston system, radiators, and other such components can’t be manufactured with injection molding due to their complicated designs and structures.

Conclusion

Injection molding is considered the best when the automotive manufacturing businesses need to produce huge volumes of plastic parts. This process not only simplifies the fabricating hurdles but also reduces the time and cost by ten folds. However, many high-end manufacturers have started to look for alternatives so that complicated car parts can be designed and fabricated with ease. This is why one needs to come up with ways for mitigating the challenges of injection molding and make it the number one fabrication method in the automotive industry.

Categories

Share On

Recent Post

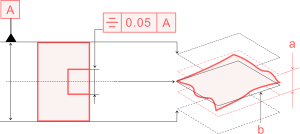

Symmetry (GD&T) Guide

Have you ever looked at a complex part and wondered

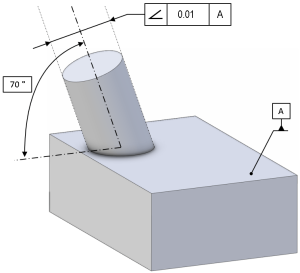

What is Angularity (GD&T)?

Have you ever looked at a technical drawing and seen