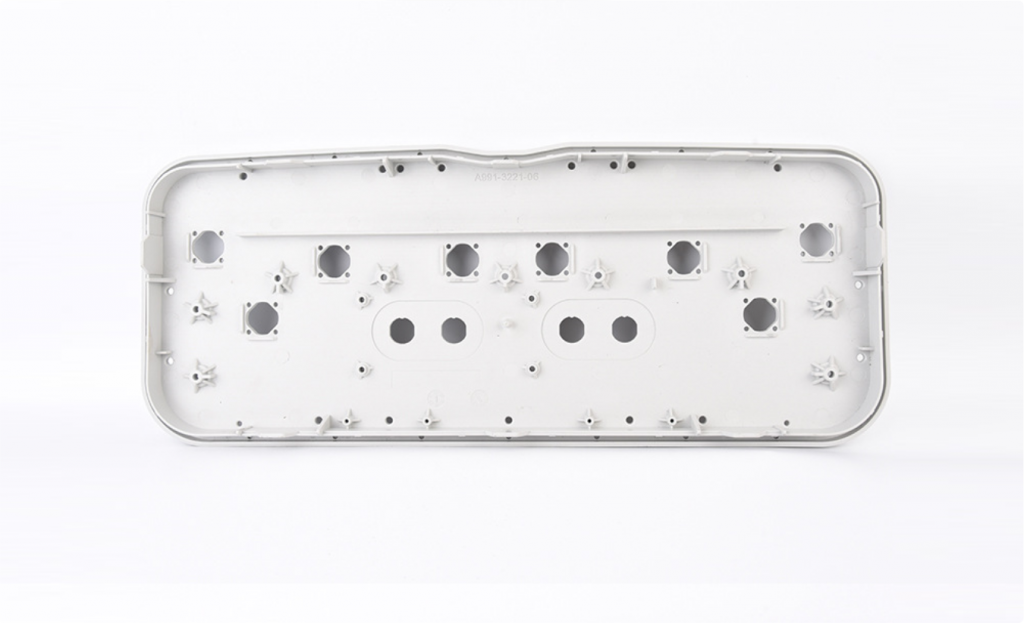

The plastics industry is very dynamic today. Plastic is one of the main modern industrial structure materials, widely used in automobiles, aerospace, electronic communications, instruments and meters, stationery, chemical, textile, medicine and health, building hardware, household appliances, and other fields. By 2004, China’s annual output of plastic parts has broken through 25 million tons. Looking into the 21st century, synthetic polymer materials will enter a period of the qualitative leap.

The position of injection molding mould

From the customs statistics of China’s mold import in 2020, plastic mold accounted for 20% of the total mold import, and injection molding mold occupies a large proportion in the whole plastic mold. The injection molding mold design is good or bad, which determines the quality and yield of injection molding parts. That is to say, whether you can add high-quality and inexpensive plastic parts, to a large extent, depends on the rationality and advanced design of injection molding mold to ensure.

Modern plastic parts production, reasonable injection molding process, advanced injection molding mold and high precision, high-efficiency injection molding equipment are the three essential factors in contemporary plastic molding processing. Lack of one will accomplish nothing. In particular, the injection mold plays an important role in fulfilling the requirements of plastic processing technology, the use requirements of plastic parts, and modeling design. Efficient, automatic equipment is only equipped with automatic mold production, which is likely to play its effectiveness. Product production and update are based on mold manufacturing and innovation as the premise.

China’s injection mold product level since 2004 has also made great progress. In terms of large injection moulds, we can produce plastic moulds for 1219mm (48in) TV, 6.5kg large capacity washing machine, car bumper, integral instrument panel, and other plastic moulds. In the aspect of precision injection mold, we can produce camera plastic mold, multi-cavity small module gear mold, etc. This also shows that our injection molding technology has reached a higher level and will play an increasingly important role in the process of national economic development.

The production and application of plastics are one of the important criteria for the investigation of a country’s science and production technology. It is self-evident that the processing and application of plastics and the speed of the development of the plastics industry have a great influence on the development of national science and technology and production and the national economy.

Throughout the development of the world economy, economic development is fast, the best-selling products, natural requirements of mold manufacturing technology wood can keep up. At present, the world mold market is still in short supply. It can be seen that the research and development of mold technology, improving the level of mold technology, to promote the development of the national economy has a particularly important significance. In Japan, mold is regarded as “the driving force to enter the rich society,” in Germany, it is regarded as “the emperor in the metal processing industry,” and in Romania, mold is regarded as “gold .”It can be affirmed that with the rapid development of modern technology, people live in the “plastic world,” injection molding will be in a very important position in the process of national economic development.

To sum up, China’s mold industry is large but not strong.

The development trend of injection mold

China’s plastic mold industry started late, the foundation is thin, and there is a big gap compared with the industrially developed countries.

But in a set with the state industrial policy and the support of a series of national economic policy and reform and open policy to lead the injection mold of China is rapidly developing, high efficiency, automation, large, miniature, high precision, no flow channel, auxiliary gas, the life of the mold in the whole plastic mold production proportion of larger and larger. From the perspective of mold design and manufacturing technology, the development trend of injection molding mold can be summarized as the following aspects.

(1) deepen the theoretical research in mold design, the research on the process principle is deeper and deeper, mold design has gradually developed from the experience design stage to the theoretical calculation design, especially when injection molding melt flow caused by the orientation, which makes the quality of plastic parts will be greatly improved.

(2) high efficiency, automation, a large number of high efficiency, automatic mold structure, such as efficient cooling to shorten the molding cycle; Gas-assisted injection molding to improve the quality of injection parts; Hot runner gating system to improve the productivity and quality of plastic parts; A variety of reliable and automatic release of products and runner condensate release mechanism to increase output, etc. High-speed automatic injection molding machine with advanced mold to improve the quality of products, improve production efficiency, reduce the cost of products has played a great role.

(3) Large, ultra-small, and high precision due to the abnormal characteristics of plastics, the application range is very wide. Plastic parts have been applied to construction, machinery, transportation, household appliances, instruments, and other industrial fields, so there have been a variety of large, precision, and high-life injection molding molds. In order to meet these requirements, a variety of die materials with high strength, high hardness, high wear resistance, and easy processing, small deformation in heat treatment, and excellent thermal conductivity have been developed.

(4) The standardization of mold and the application of mold standard parts will greatly affect the mold manufacturing cycle, improve mold quality, and reduce mold manufacturing costs. Carry out mold standardization work, make a template, guide pillar, pushrod, and other general parts standardization, serialization, commercialization in order to adapt to large-scale production of injection molding mold.

(5) Expand the research of injection molds with various special structures In order to meet the functional requirement of the plastic parts, should further explore the mould structure with a special performance, such as low foaming molding mould, double color injection molding mould, thermosetting plastic temperature flow injection molding mould, thermosetting plastic injection molding, reaction injection molding mould, BMC molding mold, countercurrent injection molding mould, liquid injection molding mold, multi-stage injection Molding mold, laminated injection molding mold, low-pressure injection molding mold, magnetic directional injection molding mold, assembly injection molding mold, etc.

(6) Fully popularizing CAD/CAE/CAM technology CAD/CAE/CAM technology is an important milestone in developing mold technology. The practice has proved that CAD/CAE/CAM technology is the development direction of mold manufacturing. At present, the conditions for popularizing CAD/CAE/CAM technology are mature. With the development and progress of computer software, technical training is increasingly simplified. In popularization and application of CAD/CAE/CAM technology, based on should vigorously promote enterprise information engineering, computer-aided process design can start gradually to computer integrated manufacturing And even to the development of virtual manufacturing, and gradually deepen and improve, used for mold design and manufacture of computer software to intelligence, integration, network and digital direction.

(7) Further strengthening rapid prototyping (RPM) Technology Rapid prototyping manufacturing technology was first introduced in the United States. It is accompanied by the development of computer technology, laser forming technology, and new material technology is a new manufacturing technology, is based on the novel discrete/stacking (that is, material accumulation) molding idea, according to the parts CAD model, fast, automatic completion of complex THREE-DIMENSIONAL entity (model) manufacturing. RPM technology is a high-tech technology integrating the latest development of precision machinery manufacturing, computer, NC technology, laser forming technology, and material science. It is recognized as a technological revolution after NC technology. This method has the characteristics of advanced technology, low cost, short design and manufacturing cycle, and moderate accuracy. RPM technology can also solve the difficult problem of the graphite electrode pressure vibration (grinding) molding of the mother mold manufacturing.

(8) Ultra-finishing and composite processing Aerospace and other sectors have applied nanotechnology. It is necessary to have ultra-high-precision mold manufacturing ultra-high precision parts. With the development of precision and large-scale mold, the ultra-finishing machining technology with machining accuracy of more than 1um and the composite processing technology integrated with electric, chemical, ultrasonic, laser, and other technologies will have a broad prospect in the future mold manufacturing.

Categories

Share On

Recent Post

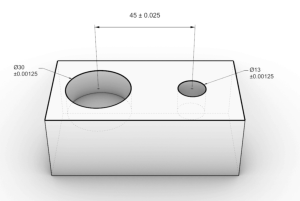

CNC Machining Design Guide

CNC machining—short for computer numerical control machining—turns a digital CAD model into

CNC Machining Guide Explained

Computer Numerical Control (CNC machining) is a cornerstone of modern