If you are looking for a machining process that can create incredibly smooth surfaces, then you should consider electrical discharge machining, or EDM. This process is often used when traditional machining methods are not possible, such as when the material is too hard or when the desired shape is too complex. The end result is a very smooth surface with no burrs or ridges. In this blog post, we will discuss the basics of EDM and how it works.

History of development

Electrical discharge machining industry was first developed in the 1940s as a way to machine difficult-to-machine materials like tungsten. It wasn’t until the 1970s that EDM began to be used more widely, as advances in technology made it possible to create smaller and more precise electrical discharges. Today, EDM is used in a variety of industries, from aerospace to medical device manufacturing.

What is Electrical Discharge Machining?

Electrical discharge machining, or EDM, is a manufacturing process that uses electrical energy to cut through metal,also known as discharge machining or electroerosion machining. It is uses electrical energy to create sparks or arcs between two electrodes, which then cut through the workpiece. This process can be used to manufacturing extremely precise shapes and holes in materials.

How does Electrical Discharge Machining work?

Electric Discharge Machining works by using electrical energy to create sparks or arcs between two electrodes, which then cut through the workpiece. The process can be used to produce a wide variety of parts and products, making it a very versatile manufacturing option.

Principle of Electrical Discharge Machining:

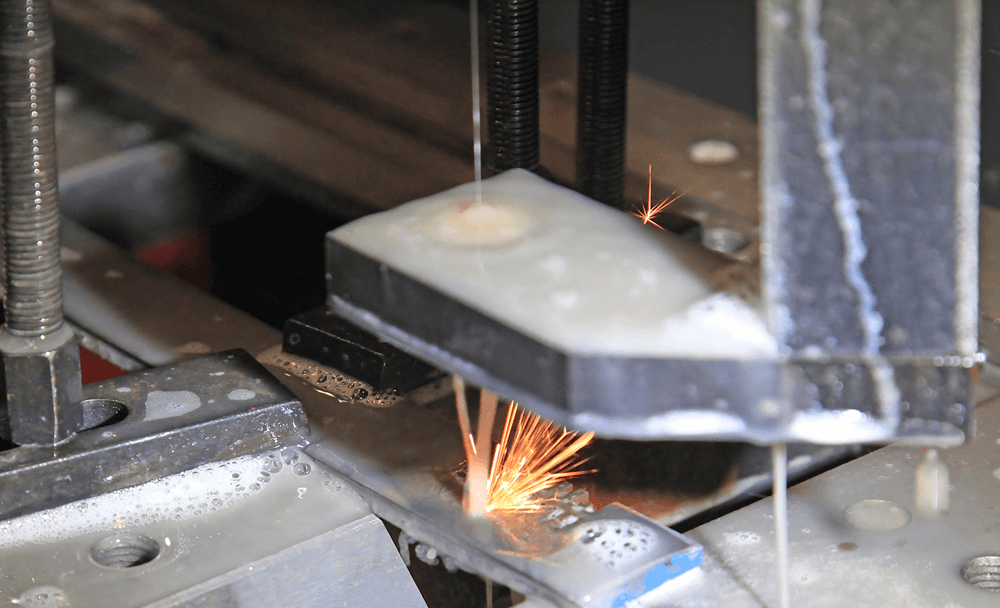

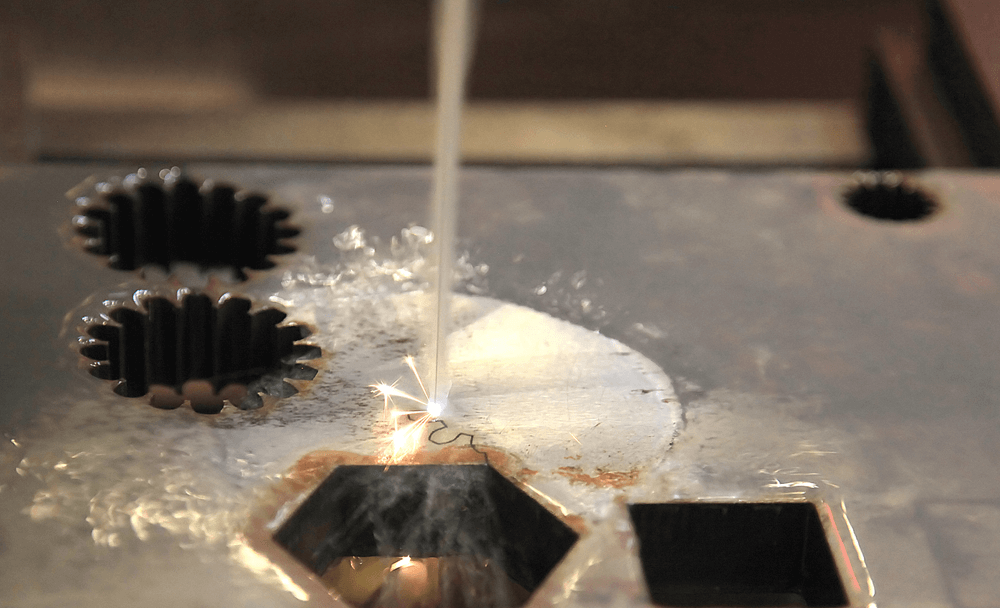

In Electrical Discharge Machining process, the tool electrode and workpiece are connected to the two poles of the pulse power supply and immersed in the working fluid, or the working fluid is filled in the discharge gap. When the gap between the two electrodes reaches a certain distance, the pulsed voltage applied to the two electrodes will decompose the working fluid and produce a spark discharge.

A large amount of heat energy is concentrated instantly in tiny discharge channels, with temperatures as high as 10,000 tons and pressure varying rapidly, so that a small amount of metal material on the working surface immediately melts, vaporizes and explodes into the working fluid. It quickly condenses into solid metal particles and is carried away by the working fluid. Tiny indentations are then made on the surface of the workpiece, the discharge is temporarily stopped, and the working fluid between the two electrodes returns to its insulating state.

Immediately after that, the next pulse voltage clicks through on the other side of the electrode, producing a spark discharge, and EDM process is repeated. Under the condition of keeping the discharge gap between the tool electrode and the workpiece constant, the tool electrode is continuously fed into the workpiece while corroding the workpiece metal, and therefore, a variety of complex contours can be machined by changing the shape of the tool electrode and the relative motion between the tool electrode and the workpiece.

What is EDM machine?

An EDM machine is a computer-controlled machine that uses electrical energy to cut through metal. Edm machine are composed of bed and column, worktable, spindle head, working fluid and working fluid circulation filtration system, pulse power supply, servo feed mechanism, spindle head and worktable accessories.

The machining dimension tolerance of general EDM can reach IT7 level and the surface roughness Ra value is 1.25.

Machining electrode

Generally need good electrical conductivity, high melting point, easy to process corrosion resistant materials, such as copper, graphite, copper tungsten alloy and molybdenum. In machining, the loss of tool electrode and product is at the same time, but less than the amount of metal removal of the workpiece, close to 0 can be ignored.

Cooling liquid

As discharge medium, it plays the role of cooling and chip removal in machining. Coolant requirements are low viscosity, high flash point, and stable medium, such as kerosene, deionized water and emulsion.

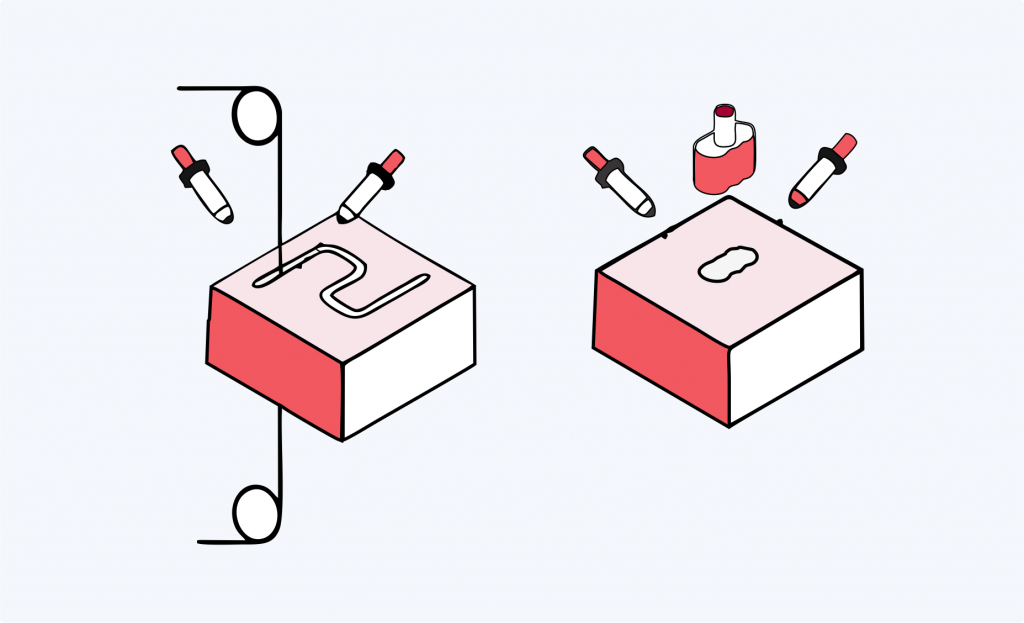

The type of Electrical Discharge Machining method

There are 3 types of Electrical Discharge Machining, sinking EDM, wire EDM and Hole Drilling EMD.

- Die sinking:

Die sinking is a machining process that uses electrical discharges to remove material from a workpiece. The process can be used to produce very complex shapes with high precision and accuracy. This type of Electrical Discharge Machining is used to create dies, molds, and other complex shapes from metal.

There are many deep grooves and narrow slits on the die surface and complex cavities, which are difficult for milling machine tools to process. This requires Die sinking EDM, and some parts of machining accuracy and surface roughness are also commonly used in EDM.

- Wire EDM:

Wire EDM is used to cut thinner materials. This type of Electrical Discharge Machining uses a thin wire to cut through the workpiece. It is often used to create small, precise parts and products.

It is divided into slow wire, middle wire and fast wire, its wire diameter with the diameter of 0.1mm~0.3mm electrode wire to process straight grain surface parts of the string, can be punch parts or concave die hole.

Edm can be machineed to fine geometry, slits and small internal radius. The wire electrode moves continuously during machining, which makes wire loss per unit length less and has little influence on machining accuracy.

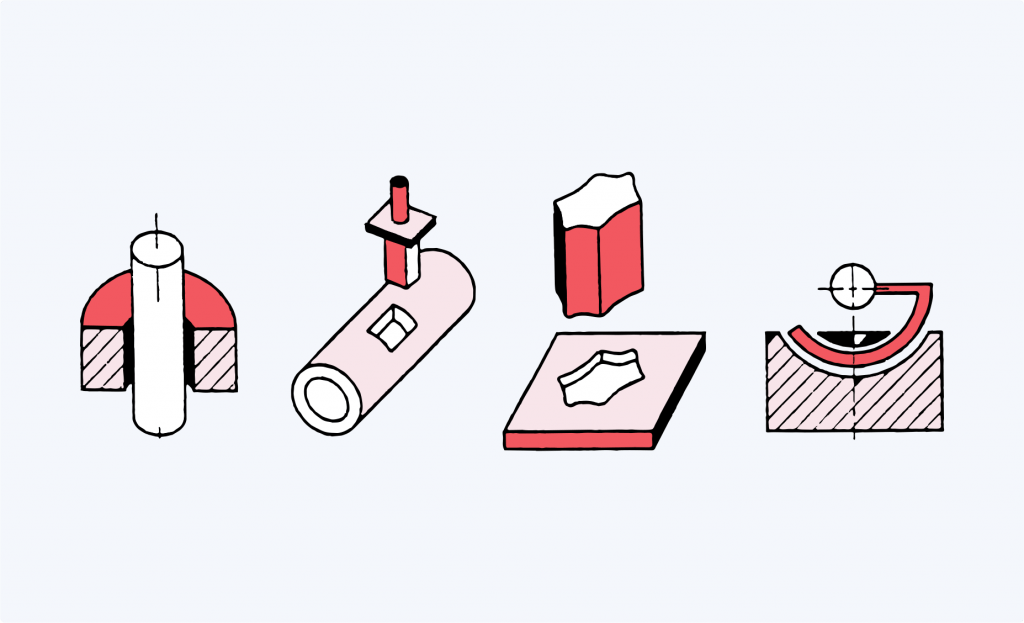

Hole drilling edm :

EDM process often used for processing type holes (round hole, square hole, polygonal hole, special-shaped hole), curve hole, 4qL, micro hole, such as cold stamping die, drawing die, extrusion die, nozzle, nozzle head of various types of holes and holes.

Hole Drilling Electrical Discharge Machining is used to create holes in workpieces. This type of Electrical Discharge Machining is often used to create small holes with a diameter of 0.004 inches (0.102 mm) or less.

The dimensional accuracy of perforation machining mainly depends on the dimension of cutter electrode and discharge gap.

The shape size of the tool electrode is mainly uniformly reduced machining clearance, smaller than the size of the predetermined hole. Its dimensional accuracy is one level higher than the workpiece, and the surface roughness should be less than the workpiece.

Edm can ensure the high precision of aperture, the straightness and cylindricity of the hole, and no burr and inclination. Hardened steel can also withstand edM. Therefore, it can prevent the phenomenon of quenching deformation of the traditional plate perforated after quenching.

- Larger hole:

When the edM is larger than the hole, the general prefabrication, leaving the appropriate allowance (unilateral allowance of 0.5-1mm or so), the allowance is too large, low productivity, edM is not good positioning.

- Fine hole: (hole less than 0.2mm in diameter. )

At present, it can process fine holes with depth to diameter ratio of 5 and diameter of 0.015mm. However, machining fine holes is less efficient because tool electrodes are difficult to manufacture and chip removal is difficult.

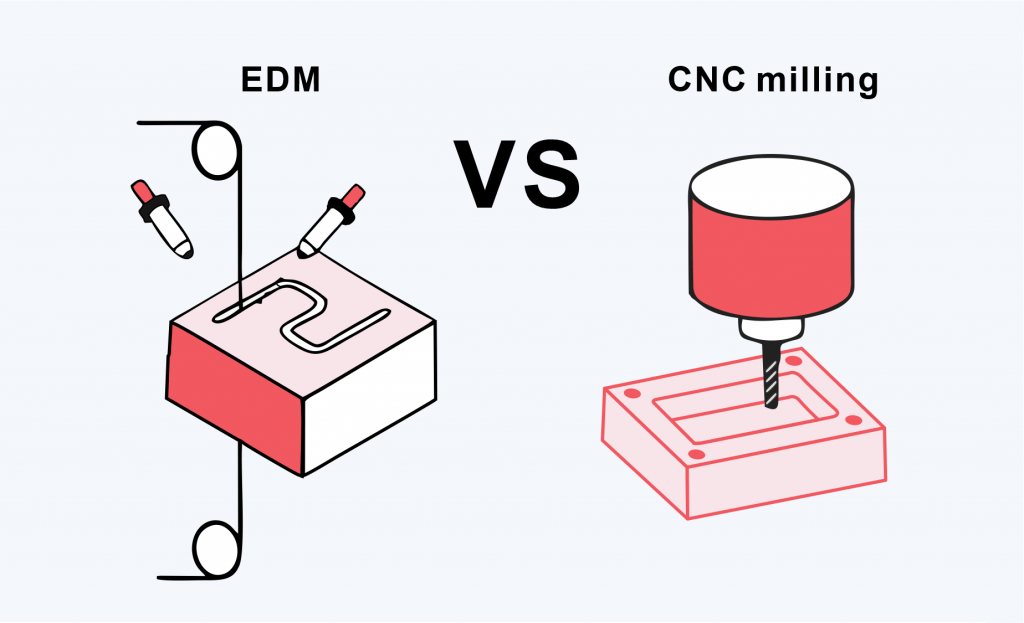

Edm VS CNC milling:

Both CNC machining and electrical discharge machining are processes that can be used for prototyping and low-volume production. CNC machining is typically used for creating parts with very precise dimensions and shapes. Electrical discharge machining is typically used for producing very complex shapes with high precision and accuracy.

- When To Use EDM:

- Manufacturing punch mould, forging mold and die casting dies,

- Machining small holes, malformed holes and screw holes ,

- Cut out parts from sheet metal,

- Machining parts of complex shape,

- Processing small mirror parts, surface roughness Ra< 0.2μM,

- Deep hole processing, mesh parts processing.

EDM is typically used when other machining processes are not able to produce the desired results. EDM can be used to machine parts with very complex shapes and tight tolerances. EDM can also be used to machine parts made from hard materials that are difficult to machine with other methods.

- When To Use CNC Machining:

- Any part can be use CNC machining, other manufacturing processes cost less than CNC machining for some special parts,

- Suitable for non-decorative surfaces, as well as textured surfaces.

- More precise parts are needed. Milling makes it easier to maintain tight tolerances.

- Non-conductive materials, EDM can only process conductive materials.

CNC machining is typically used when parts do not require very tight tolerances or complex shapes. CNC machining is also a good choice for low-volume production runs. CNC machining can be used to create parts from a variety of materials, including metals, plastics, and composites.

Disadvantages

① The initial cost of setting up an EDM machine is high.

② EDM machines are slow, with a typical machining rate of 15 cm³/hr.

③ It is difficult to machine internal corners and other complex shapes.

④ There is a limit to the depth of the hole that can be machined.

⑤ EDM produces a lot of sparks, which can be dangerous.

⑥ The accuracy of the EDM process depends on the operator’s skill.

⑦ EDM machines are noisy and produce a lot of smoke.

Despite these disadvantages, electrical discharge machining is still a popular choice for many manufacturers because it offers a unique set of advantages.

Advantages

There are many advantages to using Electrical Discharge Machining. Some of the advantages include:

- Ability to machine conductive materials

It can process conductive materials, and the material can be first heat treatment and processing, to avoid the deformation of the product after heat treatment. But the material must be electrically conductive to be machined using EDM.

- Create complex shapes

EDM cutting in addition to the inside of the product corner need to pay attention to the influence of wire and clearance, the basic can be processed any shape of the product.

- Low waste

Save materials. Because the metal wire is only about 0.3mm, so after processing, the knife edge of the product is very small, which greatly improves the material utilization rate and reduces the material cost. This characteristic makes the edM processing of precious metals has incomparable advantages over other processing.

- High Quality

The machining process is almost not affected by heat, so it can reduce the thermal shock layer, high machining quality of the workpiece.

- High precise

It can cut about 0.05mm narrow slit, wedM efficiency is generally 20-60 mm 2/min, the maximum is 300 mm 2/min, machining accuracy is generally (+ 0.01-0.02mm), the maximum is (+0.004 mm). The surface roughness is generally R2.5-1.25 micron, with a maximum Ralpha of 0.63 micron, and the cutting thickness is average. 40-60 mm, up to 600 mm thick.

Conclusion

EDM is a popular choice for many manufacturers because of its unique set of advantages. Some advantages include: ability to process conductive materials, create complex shapes, low waste, high quality and high precision. EDM is also used in a variety of industries, such as manufacturing, machining small holes, and cutting parts from sheet metal. Despite some drawbacks, EDM remains a popular choice for many manufacturers.

If you have any questions about EDM or would like to learn more about this versatile machining process, please contact us today. We are happy to answer any of your questions.

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

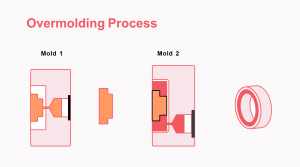

What is Overmolding? A Complete Guide

In today’s manufacturing world, creating durable, functional, and aesthetically pleasing

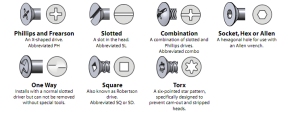

A Complete Guide on the Types Of Screw Head

You’ve probably stood in front of a confusing display of