CNC laser cutting is a technology that has been around for many years, but it is still somewhat new to the general public. In this article, we will discuss what CNC laser cutting is, how it works, and the available types of machines. We will also talk about when to use laser cutting and the advantages of using this technology.

Lear more about CNC machining: What is CNC milling? / What is CNC turning?

What is CNC laser cutting?

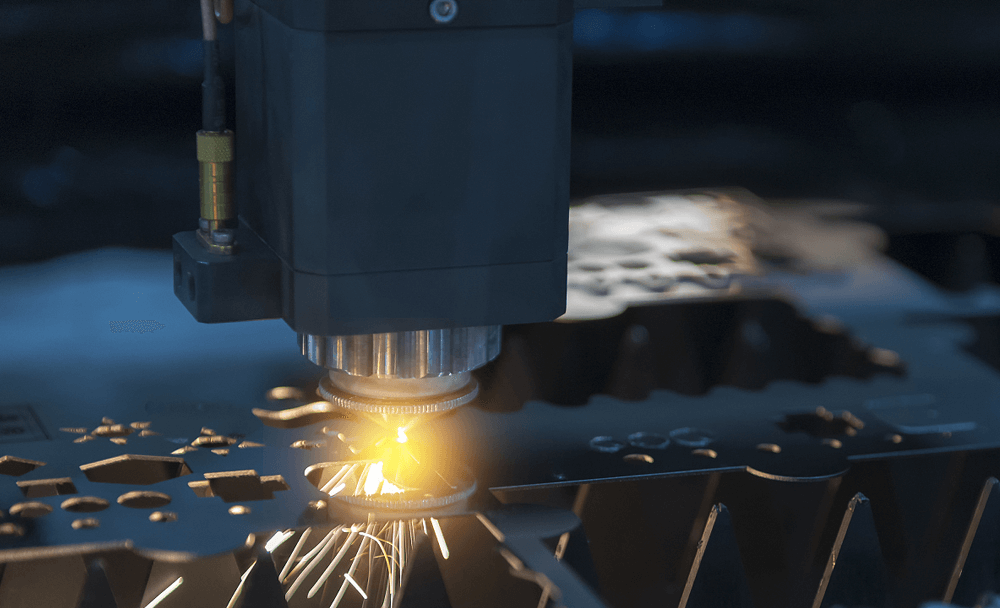

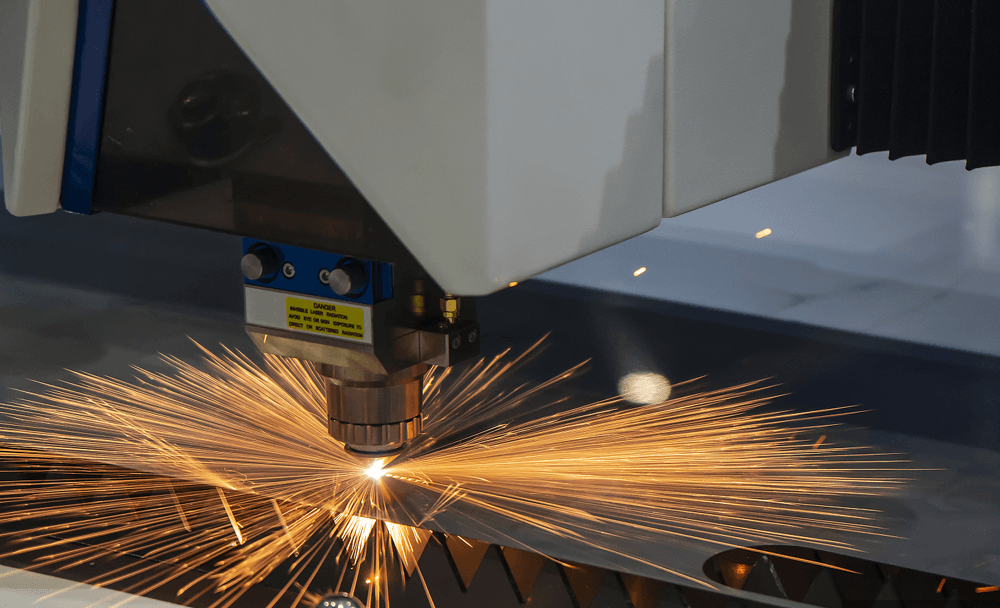

Laser cutting refers to using a laser emission beam in the product above the hole, according to the horizontal movement to the corresponding gap called laser cutting. It is used for various applications, including cutting, engraving, and Marking. It is characterized by high machining accuracy, especially suitable for CNC cutting complex shapes and small holes.

Computer numerical control (CNC) laser cutting usually uses optics, auxiliary gas, and guide systems to guide and focus the laser beam into the workpiece. The material is placed on a bed, and the laser cuts it according to the specifications that are inputted into the computer. This process can be used to cut almost any type of material, including metals, plastics, glass, and wood.

How does it works?

Laser is the use of material excitation to produce light; light with a strong temperature, in contact with the material, can quickly melt on the material’s surface, forming a hole, according to the movement of the point to point to form a cut.

The laser cutting process is quite simple. First, the material is placed on a bed, and the computer controls the laser. The laser will then cut through the material according to the inputted specifications into the computer.

Laser cutting process steps:

Prepare the material to be cut and secure it on the work surface.

Adjust the appropriate parameters according to the material and thickness.

Please select the corresponding lens and nozzle according to the cutting parameters, and check whether they are in good condition.

Adjust the cutting head to proper focus.

Check and adjust the nozzle center.

Sensor calibration of laser head.

To check cutting gas, input an open auxiliary gas command to observe whether it can be well ejected from the nozzle.

Material trial cut, check section, adjust process parameters until they meet production requirements.

Write cutting program according to the workpiece requirement, and import into CNC.

Move the cutting head to the starting point and press “Start” to execute the cutting procedure.

3 types of laser cutting machines

There are three main types of laser cutting machines: CO₂, fiber, and YAG.

- CO₂ lasers:

CO₂ lasers are the most common type of industrial laser. They are used for a variety of applications, including cutting, engraving, and Marking. CO₂ lasers are available in a variety of power levels, from 30 watts to over 100 kilowatts.

CO₂ and YAG lasers have similar structures, but are used in different ways. CO2 lasers with lower power levels are commonly used in industrial welding and cutting due to their reasonable price.

- Fiber lasers:

Fiber lasers are becoming increasingly popular due to their high efficiency and low maintenance costs. Fiber lasers are available in powers ranging from 300 watts to over 20 kilowatts.

Fiber lasers with solid-state structure and high power output can reduce the cost of consumables and effectively cut a variety of materials.

- YAG lasers:

YAG lasers are not as common as CO₂ and fiber lasers, but they are still used for some industrial applications. YAG lasers are available in powers ranging from 500 watts to over 100 kilowatts.

YAG lasers have high peak output and provide excellent metal marking and etching results.

2 kinds of laser cutting perforation method

Any thermal cutting technique, except in rare cases where the edge of the plate may be started, generally requires a small hole in the plate. Earlier in the laser stamping compound machine is to use a punch out of a hole, and then used the laser from the hole began to cut for lasers without a stamping device.

There are two kinds of perforation based on the method:

Blast drilling:

The material is hit with a continuous laser beam to create a crater in the center. Then the molten material is quickly removed by oxygen flowing coaxially with the laser beam, creating a hole.

This method is suitable for mild steel, non-ferrous metals, and other materials. The advantage of this method is that the hole is clean, round, and burr-free. The disadvantage is that the perforation time is about 30 seconds to one minute long.

Pulse drilling:

Pulse drilling is to use a high-energy-density laser beam to heat the workpiece locally, so that the material vaporizes and forms a hole. This method is suitable for all kinds of materials. However, this method should use a laser cutting machines with high output power.

The advantage of this method is that it is fast, about 0.05 seconds per hole. The diameter of the hole produced by this method is smaller than Blast drilling, and the quality of the hole is better than that of the blasting hole.

Laser cutting materials:

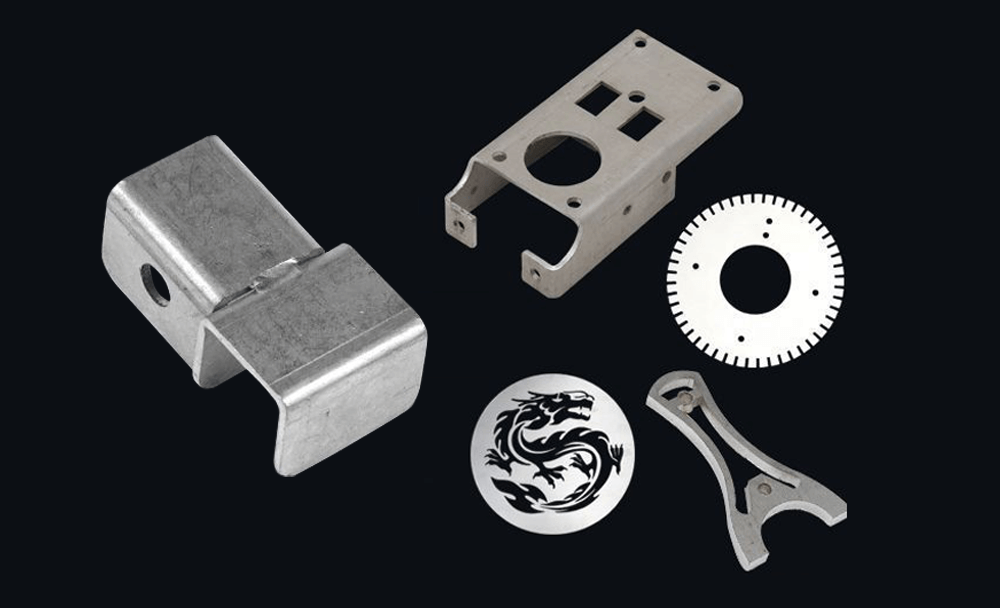

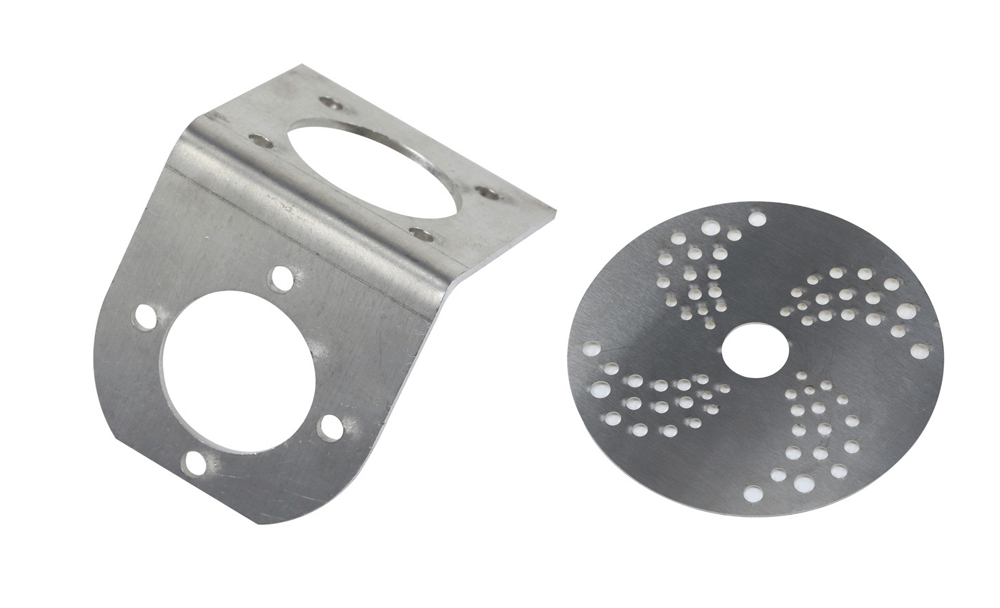

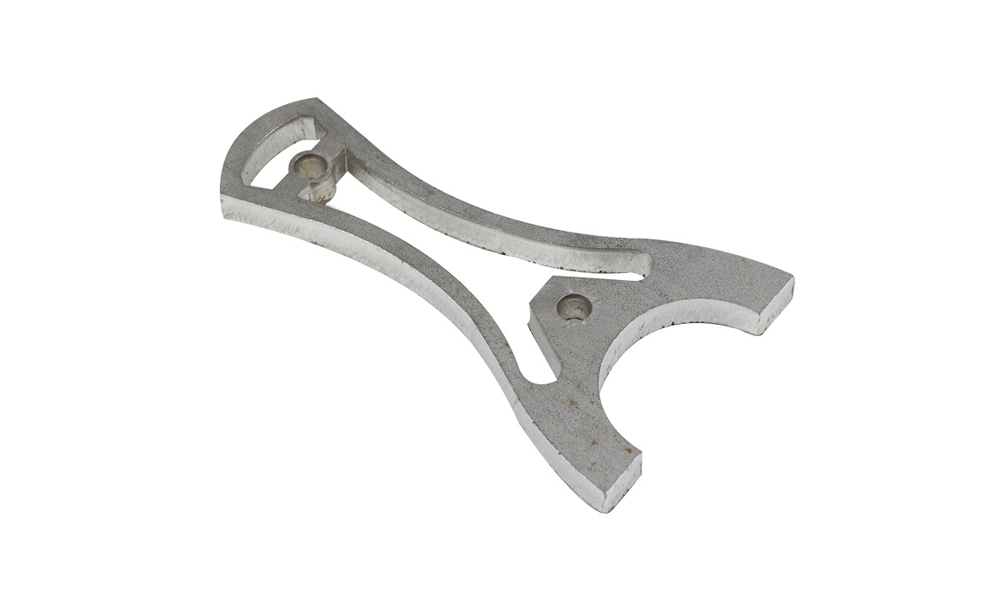

The laser can be cut in many product materials, such as stainless steel, mild steel, aluminum, copper, acrylic, knife template, cloth, leather, and other industries can use laser cutting, so laser cutting is a new solution in many industries.

- Stainless steel:

Laser cutting is easier than cutting stainless steel sheets. With the high-power YAG laser cutting system, the maximum thickness of stainless steel cutting has reached 4mm. The low-power YAG laser cutting system we developed can cut stainless steel up to 4mm thick.

- Alloy steels:

Most alloy steels can be laser cut with good edge quality. However, tool steel and hot die steel with high tungsten content will have corrosion and sticky slag when laser cutting.

- Aluminum & Aluminum Alloy:

Aluminum is another popular material for laser cutting. It can be cut with either a CO₂ or fiber laser. Aluminum cutting belongs to melting cutting, and auxiliary gas blows away the molten material in the cutting area, so as to obtain better section quality. Currently, the maximum thickness of the cut aluminum plate is 1.5mm.

- Carbon steel:

The laser cutting system can cut the maximum thickness of a carbon steel plate close to 20mm, and the thin plate of its slit can be narrow to about 0.1mm. Laser cutting of mild steel, the heat affected area, is minimal and cut to meet the level, smooth, good verticality.

- Brass & Copper:

They are difficult material to cut with a laser. It requires high power and can be challenging to find the right cutting parameters. Both materials have high reflectivity and very good thermal conductivity.

- Non-metallic material:

Lasers can cut organic materials such as plastics (polymers), rubber, wood, paper products, leather and natural and synthetic fabrics; At the same time can also cut quartz, ceramic and other inorganic materials, but also can cut new lightweight reinforced fiber polymer and other composite materials.

When to use CNC laser cutting?

CNC laser cutters flexibility, high cutting speed, high production efficiency, short product production cycle, for customers to win a wide range of market, the effective life of the technology is long, more than 2 mm thickness of the plate mostly using cnc laser cutter.

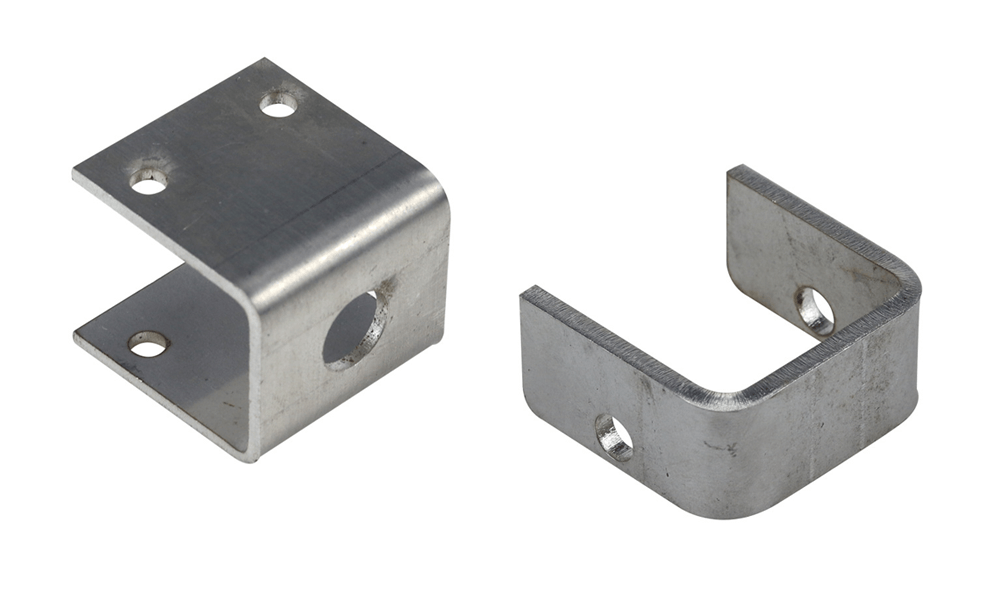

Laser cutting is a process revolution in sheet metal fabrication process. Generally speaking, it is recommended to use a laser cutting machine for cutting metal materials such as mild steel plates within 12mm and stainless steel plates within 10mm.

Laser cutting machine no cutting force, processing no deformation: no tool wear, good material adaptability: whether simple or complex parts, can use a laser precision rapid prototyping cutting

The application industry of CNC laser cuting

Sheet metal fabrication (Metal housing or structural parts)

Decoration and advertising industries

Packaging and printing industries

Engineering manufacturing, shipbuilding industry

Aerospace industry ( engine flame barrel, thin wall casing, aircraft frame, etc. )

Automobile structure manufacturing. (Cutting body sheet and various curved parts with complex shapes)

Advantages

There are many advantages to using laser cutting, including:

- Precision:

Laser cutting can produce very precise cuts. The computer control system allows for accurate cuts within 0.001 inches.

- High quality:

The incision is narrow (generally 0.1-0.5m), high precision, the incision surface roughness is good (general Ra is 12.5-25 μm), and the cutting seam can be welded without reprocessing.

The following 5 standards can measure laser cutting quality.

Cutting surface roughness Rz

The size of the residual debris from the incision

Cut edge verticality and slope U

Cut edge fillet dimension R

Flatness F

- Fast Speed:

Laser cutting is a speedy process. For example, Use CO₂ laser cutting. The 8mm thick carbon steel cutting speed is 1.6m/min; the 2mm, thick stainless steel cutting speed, is 3.5m/min. It can cut through the material much faster than traditional methods such as sawing or milling.

- Flexibility:

There are many kinds of laser cutting materials, including metal, non-metal, metal, and non-metal-based composite materials, leather, wood, fiber, etc.

- Low cost:

The initial cost of a laser cutting machine may be high, but the operating costs are relatively low. There are no consumables required, and there is very little maintenance needed.

Disadvantages

Laser cutting due to the limitation of laser power and equipment volume, laser cutting can only cut the medium and small thickness of plate and pipe, and with the increase of workpiece thickness, cutting speed decreased significantly.

CNC laster cutting VS Plasma / Water cutting

CNC laser cutting has many advantages over the flame, plasma, and water. Because the heat application of the laser is tightly concentrated, less power is required, and the material’s heat-affected zone (HAZ) is reduced.

The precision of the CNC laser cutting process is higher than plasma cutting and water cutting; Many high-end industrial laser cutters have an accuracy of 10 microns and a repeatability of 5 microns. CNC lasers can economically cut and etch a wide range of materials, even nonmetallic materials that cannot be cut by flame or plasma.

Conclusion

CNC laser cutting is a versatile and precise method for cutting various materials. It is fast, efficient, and has a low cost of ownership. Consider a CNC laser cutting machine if you are looking for an industrial laser cutter. Please contact us if you have any questions about CNC laser cutting or want more information.

This is the end of the blog post. Please get in touch with us if you have any questions about CNC laser cutting or want more information. We would be happy to help you select the perfect laser cutter for your needs. Thanks for reading!

Try Made by Aria Now

All information and uploads are secure and confidential.

Categories

Share On

Recent Post

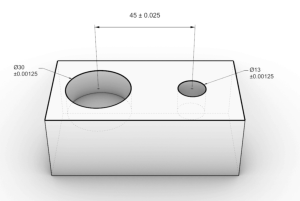

CNC Machining Design Guide

CNC machining—short for computer numerical control machining—turns a digital CAD model into

CNC Machining Guide Explained

Computer Numerical Control (CNC machining) is a cornerstone of modern