The relationship between injection cycle time and production injection molding cost. On the premise of ensuring product quality, the shorter the plastic cycle time, the better, so that the more production quantity, the lower the manufacturing cost of the unit product. Injection cycle time includes what elements: injection time, pressure holding time, cooling time, mold opening time, top out time. The main ways to shorten the molding cycle time: to decrease the size of the plastic parts wall thickness/port so as to reduce the distance/plunger stroke, combining a model product, a mechanical hand quickly after operation, speed up the open/close the door, reduce the adhesive and mold piece, the correct selection of cooling time, reasonable setting opening/closing speed and plunger speed/number, etc. Shortening injection cycle time is to improve production efficiency.

Suppose the injection molding mold maintenance work is not in place. In that case, there will often be mold failure in the production process. It is necessary to frequently stop production and maintain the mold, which affects the smooth production and the stability of the quality of plastic parts and causes economic losses to the enterprise. For proper maintenance work, Aria plastic shell batch customization is needed to mold and other production tools. To ensure that the production process will not lose the chain failure. After maintaining the mold, there will not be a series of problems behind to ensure smooth production. Mold maintenance is urgent, and it is an important guarantee of production in place.

In addition, there is a relationship between quality and production cost. “Product quality is the life of an enterprise,” the high return and defective rate of plastic parts is a greater waste. The enterprise’s reputation is affected while causing great economic losses. Suppose the injection molding production of product quality control is not good. In that case, the enterprise’s competitiveness will be a high defect rate, waste, low output, return rework, delayed delivery, and even lost customer orders. These are things we don’t like to see. If injection molding processing production appears batch return, the loss will be greater. Quality is something we should never take lightly. Only good quality can have a good reputation. With good word of mouth, customers naturally believe you. Of course, orders will continue to come.

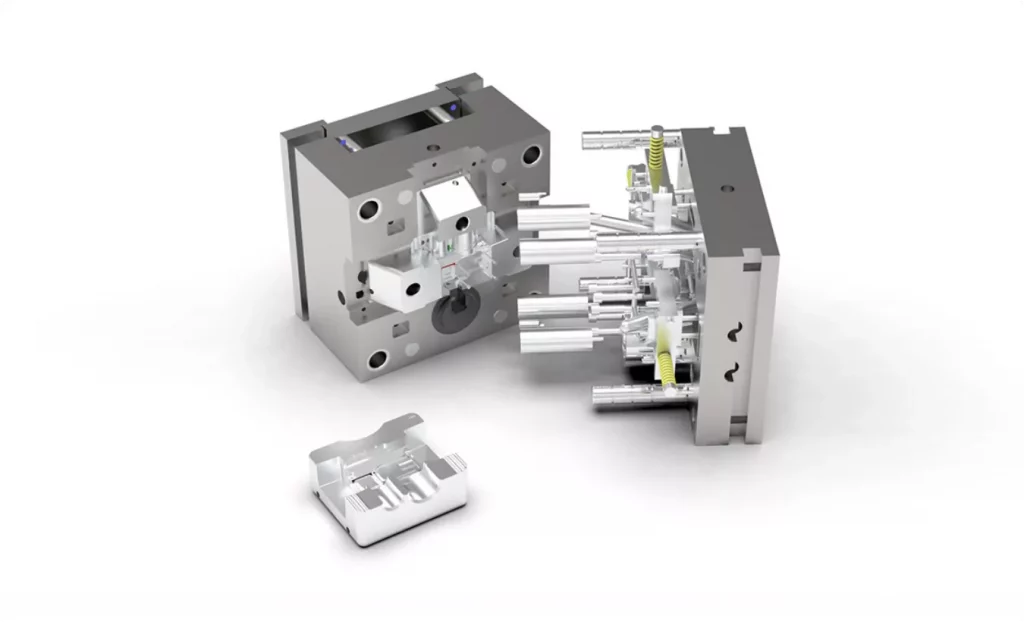

Injection mould plays a very important role in people’s life. Most of the tools used in people’s lives are produced by injection mould processing. Injection mold is a specialized production of plastic products tools but also can help plastic products more complete structure, more accurate size tools.

On many platforms, you can see the figure of injection mold. With the rapid development of the plastic industry and the increasing number of plastic product application platforms, injection mold production standards are constantly improving. The traditional mold production process is no longer suitable for the present industry.

Injection mold plays a very important role in people’s life, Beijing plastic shell batch customization, now the application of tools in people’s lives, very many are produced by injection molding mold processing; Injection mold is a specialized production of plastic products tools but also can help plastic products more complete structure, more accurate size tools.

Categories

Share On

Recent Post

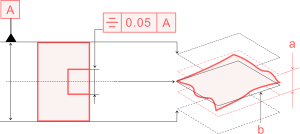

Symmetry (GD&T) Guide

Have you ever looked at a complex part and wondered

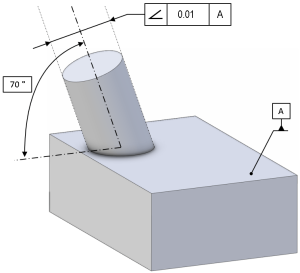

What is Angularity (GD&T)?

Have you ever looked at a technical drawing and seen