China’s Long History in Manufacturing

For many decades, China has been a world leader in manufacturing. Countless products sold in every corner of the globe arrive with the familiar “Made in China” label. Companies have come to rely on quality Chinese manufacturing to provide them with affordable, well-made items.

The initial surge in manufacturing in China was a result of the availability of manual labor. The large labor market could easily supply any facility with enough workers to produce large quantities of goods. In time, the manufacturing systems in China became more advanced, involving higher levels of technology like injection molding services.

How to Choose an Injection Molding Manufacturer in China?

The excellent reputation of Chinese manufacturing facilities has made them a top candidate for any company in search of a factory. This is as true of injection molding factories as it is of many other types of production. If you are marketing products that are built with this technique, there are several reasons why you should choose to have your injection molding in China.

1. Quality:

Without a doubt, your top concern in choosing an injection molding manufacturer will be quality. No other dimension of the process matters if you are unable to sell a durable, functional good. As a result, you will always be looking for manufacturers that can provide unparalleled quality for your goods. You will also expect that they will be able to provide that consistency from one production cycle to another for as long as you are placing products on the market.

The Chinese manufacturing industry has built its reputation first and foremost on quality. Across the generations, our workers have always been fully focused on sending retailers a product that they can sell with confidence. Measurements, colors, and all other aspects of the product will always meet or exceed your expectations without question.

When your reputation and your company’s profitability are on the line, there is no substitute for the quality you will receive from injection molding products manufactured in China.

2. Cost:

Profit margins consistently run razor-thin. In most industries, the retail and wholesale markets are so competitive that there is no room for price differentiation. The only way to make more profit than a competitor is to find ways to lower costs, and Chinese manufacturing can do that.

The efficiency, skill, and experience of Chinese manufacturing work smoothly, with minimal disruptions and maximum utilization of materials, utilities, labor, and other inputs. By making the best possible use of your investments in inputs, Chinese manufacturers are able to get your products out the door with an optimum cost structure that doesn’t cut corners.

Your entire business model relies on an effective plan for containing costs. With Chinese manufacturing, you will always know that your input dollar will be used efficiently in a way that improves the end product. Our facilities will never waste your investment on an ineffective system or careless management.

3. Delivery Time:

Inaccurate delivery times are among the most expensive problems you can have. Your supply chain must be a finely-tuned process. If products do not arrive in time for shipments, orders will be missed and contracts can be lost. If products arrive too early, you are forced to spend extra money to store, organize, and secure them until they are needed on the market.

Chinese manufacturing facilities are the best in the world at staying on schedule. Their decades of experience have made them experts at setting realistic goals. Managers will never promise a delivery date that they cannot meet. Instead, they will provide an honest and accurate assessment of the time needed to complete an order in a satisfactory way.

This is possible because Chinese workers know how to maintain an appropriate pace, moving quickly in their work without rushing. The result is that the injection molding facilities will always meet the time frame you determine for the delivery of your product. Your shipping, storage, and management plans will remain on track, keeping your customers satisfied and your business on track.

4. Production Capacity:

When your company places an order for injection molding services, you have an expectation that the manufacturer can meet the order without increasing capacity. A manufacturer that cannot meet the quantity with their existing resources will have to add space, procure machinery, and hire new workers. These processes are costly and time-consuming, and they often lead to an inferior product from inexperienced workers.

Injection molding in China is done in well-managed facilities with known capabilities. Any manufacturer that takes on your order will do so only if it can meet output quotas without costly and hasty expansions. Chinese manufacturing managers always have the information necessary to generate accurate calculations of the potential output of their facilities. They never guess at their capacity but instead rely on historical data to ensure that the output they predict can be met.

The better your information is about production capacity, the better your decisions about other elements of the marketing process. With injection molding manufacturer in China, capacity calculations are always accurate.

The Choice is Clear

Manufacturing a product requires two basic things: a quality product made in an affordable way. Many companies have explored various avenues to try to meet this goal only to find that their best option is to get their manufacturing done in China.

With specialized manufacturing processes like injection molding, Chinese factories can meet your high standards for every aspect of the production process. Your products will achieve a higher level of quality than ever, one that will be maintained year after year. Costs will be controlled, allowing you to achieve a sustainable level of profitability. Our facilities will always meet your production deadlines, and they will never fail to provide the required output.

When it is time to choose a facility for injection molding manufacture, choose to have your products follow in the footsteps of so many others and have them made in China.

Categories

Share On

Recent Post

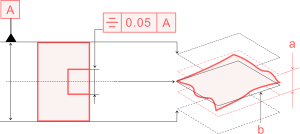

Symmetry (GD&T) Guide

Have you ever looked at a complex part and wondered

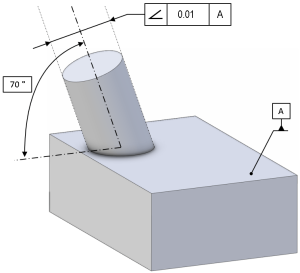

What is Angularity (GD&T)?

Have you ever looked at a technical drawing and seen