1. The definition of impact strength

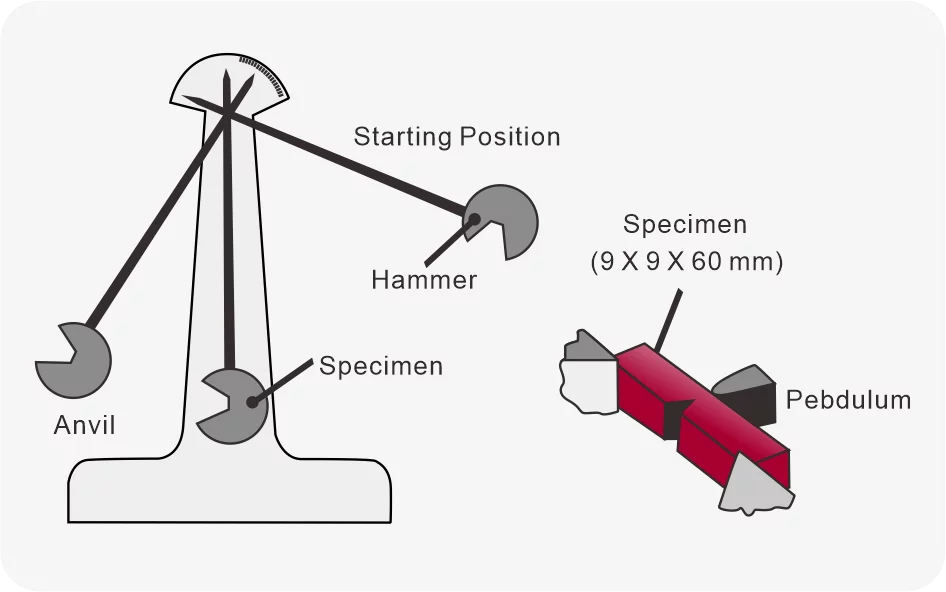

Impact strength is the strength of resistance when the object is affected by impact force or impact force. Impact strength is to test the impact resistance of a material (or product) so as to reflect the ductile strength of the material or product.

The impact strength is not expressed by the fracture stress of the material (Kg/cm²) but by the total energy that can be sustained at fracture (KGF-CM) or the fracture energy absorbed per unit of fracture area of the sample (KGF-cm /cm² or J/m).

2. Test method for impact strength

You can expect significant savings when exporting from China. A single cavity plastic injection can cost anywhere between $1000 and $5000. The typical expense is $12,000 while a more complex design costs $80,000 or more. Keep in mind that manufacturing quotes from China often exclude shipping costs, duty shipping, translators, and international insurance.

The impact strength of simple beam without notched sample:

The impact strength of simple beam without notched sample: the impact strength refers to the ratio of the impact energy absorbed by the non-notched sample under the impact load and the original cross-sectional area of the example, in kJ/m2.

Notched sample supported beam impact strength:

The impact strength of simple beam without notched sample: the impact strength refers to the ratio of the impact energy absorbed by the non-notched sample under the impact load and the original cross-sectional area of the example, in kJ/m2.

The difference of impact test between notched and unnotched specimens:

The impact strength of spline non-notched specimens with the same shape is larger than that of notched specimens. When impacted, the sample fracture must occur in this weak place, and all the impact energy can be absorbed in this local place, which is called stress concentration, so as to improve the accuracy of the test.

3. The reference index for impact strength

The test method for impact strength is usually referred to as the ASTM D256 standard. Its principle is to use the cantilever beam to let the pendulum fall freely and hit the notched specimen fixed unilaterally, and then calculate the energy consumed (usually, the temperature will be specified).

Impact strength can generally be used as a reference for toughness levels between different plastics. Generally speaking, plastics with high impact strength have higher strength and higher flexibility, that is, higher toughness. But it is not recommended as the plastic index of overall strength because some plastic is sensitive to the concentrated stress of incision. That is to say, without incision strength, performance is excellent, but once has the gap, the intensity will drop quickly, such as nylon and acetal plastic. For this type of plastic, the recommended design must increase the R Angle. It is best to avoid designs with acute angles to avoid the possibility of stress-concentrated fracture. In addition, some plasticizer suppliers will also provide non-notch impact test values.

Categories

Share On

Recent Post

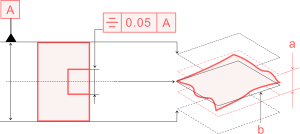

Symmetry (GD&T) Guide

Have you ever looked at a complex part and wondered

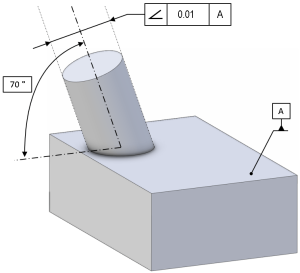

What is Angularity (GD&T)?

Have you ever looked at a technical drawing and seen